A self-learning assistance system for the manufacturing industry

Tuesday, 15 March, 2022

Efficiency rates for production machinery frequently fall far below what technology could achieve. A common reason is that experienced employees are not always available when a failure occurs, while other employees lack the experience to solve the actual cause. That is where MADDOX comes in: a smart and self-learning assistance system that uses machine learning methods to analyse machine and process data. Via pattern recognition it also searches for similarities in failures and downtimes that occurred in the past. The system was developed by Peerox GmbH, a spin-off of the Fraunhofer Institute for Process Engineering and Packaging IVV.

During machine downtime it usually takes the knowledge and experience of senior colleagues to fix it. However, they are often absent at these crucial moments, leaving less experienced staff to find the cause themselves to fix it. Even if extensive documentation is provided, it can be a major challenge to find the right information when a failure occurs and this puts the staff under unnecessary pressure. As a result, the actual cause of a failure is rarely resolved: instead they frequently keep recurring.

These common scenarios in the manufacturing industry are the focus of the Peerox GmbH. Their intelligent and self-learning assistant system, MADDOX, helps to increase efficiency in manufacturing, reduce waste and contribute to more economical and ecological production. Examples can be found in the food, cosmetics and pharmaceutical industries. Peerox was founded in the summer of 2019 as a spin-off of Fraunhofer in Dresden by Andre Schult and Markus Windisch.

“Many production facilities can barely get their efficiency rate over 60%: there is a lot of room for improvement,” said Andre Schult, CEO of Peerox GmbH. “For the most part, the problem originates by not fixing the actual cause of the failure — for example, an operator cannot tell if the slider is jammed, the vacuum is clogged or if the root of the failure is something completely different.”

Of course, there are employees that have the practice and the necessary knowledge but often are unavailable in emergencies. Considering demographic changes, shortage of skilled staff and higher turnover rates, the manufacturing industry has become more and more dependent on the practice and knowledge of their experienced employees, which causes an increasingly serious problem. Peerox GmbH addresses this issue by digitalising employees’ practical knowledge in MADDOX.

Knowledge cards help to find the cause and solution

“Employees often have no idea what phrase to use when searching for the cause of a failure,” Schult explained. “For example, if a crushed yoghurt container causes machinery downtime, they could search within the database for ‘belt’, ‘container’, ‘strap’ or some other keyword. But generally speaking, if they do not find what they are looking for quick enough, they do not see the point in doing some further searching or using the database at all.

“MADDOX therefore, is a data-driven solution that uses machine data such as pressure curves, temperatures, photoelectric sensor signals or error codes.”

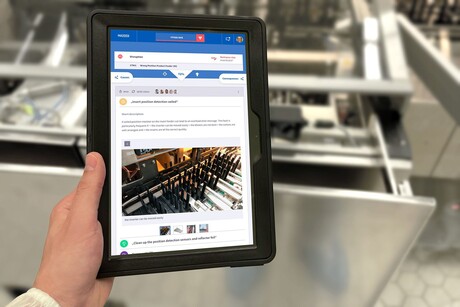

The self-learning search algorithm uses machine learning algorithms to analyse machine data and creates categories consisting of similar data patterns. Those are then linked to digital knowledge cards, where employees can use text, images and video to create visual documentation of failures and solutions — similar to a wiki page. If a failure occurs in the machinery, the algorithm analyses the data patterns, searches for similar categories and displays the relevant knowledge card to the user via a tablet that is not connected to the platform.

If that particular problem (eg, a dirty nozzle) already occurred four weeks ago, MADDOX will suggest a possible solution that the operator can either reject or confirm, and in return, MADDOX learns what database entries have proven to be helpful in which situation. This trains the algorithm, allowing it to learn quickly. A specialised pre-processing of data and dimension reduction allows the algorithm to have a rapid learning curve.

Digital assistants with psychological expertise

“Overall, MADDOX acts like a digital colleague that is always there to offer a helping hand,” the engineer said.

The psychological component also plays an important role. Several features in the Linux-based knowledge management system incorporate human impulses like helpfulness and appreciation. This in return encourages people to use the system frequently, motivating users to confirm, reject, correct and expand the entries, as well as to share their practical knowledge. It was the team’s longstanding collaboration with engineering psychologists at TU Dresden that made it possible to integrate these fundamental features into the assistant.

“That is the secret that differentiates us from other knowledge management systems,” Schult said. “We incorporate the psychological component, which allows us to increase engagement, improve documentation and reduce operating costs.”

The company currently specialises on the processing and packaging industry. In the long run, they also plan to target other sectors such as the semiconductor, automotive and chemical industries. MADDOX is currently deployed for pharmaceutical packaging at Bayer AG in Leverkusen.

Orro launches asset discovery service for OT

Australian IT solutions provider Orro has announced it is offering its Digital Asset Discovery...

Rockwell launches factory-scale digital twin technology

Rockwell Automation has launched its Emulate3D Factory Test digital twin software at NVIDIA GTC...

OFS launches AI-based productivity solution for manufacturing

Australian-built generative AI software includes real-time insights facilitating a...