NVIDIA announces GenAI and services to support digital twins and robotics

NVIDIA has announced major advancements to Universal Scene Description, or OpenUSD, that will expand adoption of the universal 3D data interchange framework to robotics, industrial design and engineering, and accelerate developers’ abilities to build highly accurate virtual worlds for the next evolution of AI.

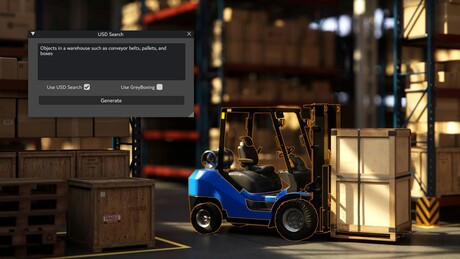

Through OpenUSD-based generative AI and NVIDIA-accelerated development frameworks built on the NVIDIA Omniverse platform, more industries can now develop applications for visualising industrial design and engineering projects, and for simulating environments to build the next wave of physical AI and robots, according to the company.

The new offerings include NVIDIA NIM microservices for AI models that can generate OpenUSD language to answer user queries, generate OpenUSD Python code, apply materials to 3D objects, and understand 3D space and physics to help accelerate digital twin development. In addition, new USD connectors to robotics and industrial simulation data formats and developer tools let users stream massive, fully NVIDIA RTX ray-traced datasets to Apple Vision Pro.

“The generative AI boom for heavy industries is here,” said Rev Lebaredian, vice president of Omniverse and simulation technology at NVIDIA. “Until recently, digital worlds have been primarily used by creative industries; now, with the enhancements and accessibility NVIDIA NIM microservices are bringing to OpenUSD, industries of all kinds can build physically based virtual worlds and digital twins to drive innovation while preparing for the next wave of AI: robotics.”

The first generative AI models for OpenUSD development, developed by NVIDIA, will be available as NVIDIA NIM microservices. The models enable developers to incorporate generative AI copilots and agents into USD workflows, broadening the possibilities in 3D worlds and helping speed the adoption of USD across a new range of industrial sectors, like manufacturing, automotive and robotics.

NVIDIA said that Foxconn, a global manufacturing leader with more than 170 factories worldwide, is already using NVIDIA’s computing platform, using NIM microservices and Omniverse to create a digital twin of a factory under development.

“Digital twins will help us accelerate the next wave of industrial manufacturing and autonomous machines,” said Zhe Shi, chief digital officer and head of the Smart Manufacturing platform at Foxconn. “NVIDIA Omniverse and the new NIM microservices will democratise the ability to develop digital twins and help our teams build physically based virtual factories faster than ever.”

NVIDIA and Siemens are also extending their collaboration to facilitate more industrial workloads using OpenUSD. Siemens will integrate OpenUSD pipelines with its Simcenter range of simulation technologies to support evidence-based decision-making and collaboration among key stakeholders.

This integration enables high-fidelity, real-time, photorealistic visualisation of complex simulation data, providing deeper insights into a product’s performance within its real-world operating environment. The work will build on Siemens’ efforts to incorporate Omniverse into its Teamcenter Product Lifecycle Management portfolio.

NVIDIA also released a connector from Unified Robotics Description Format to OpenUSD, letting roboticists seamlessly bring their robot data across applications, including for design, simulation and reinforcement learning.

OFS launches AI-based productivity solution for manufacturing

Australian-built generative AI software includes real-time insights facilitating a...

Australia the fourth most popular target for industrial cyber attacks: report

Report finds wireless networks found to be unprotected as threats to critical...

Manufacturing now a primary target for cyber attacks: report

Dragos reports that OT/ICS cyberthreats are escalating amid geopolitical conflicts and...