Festo identifying waste with artificial intelligence

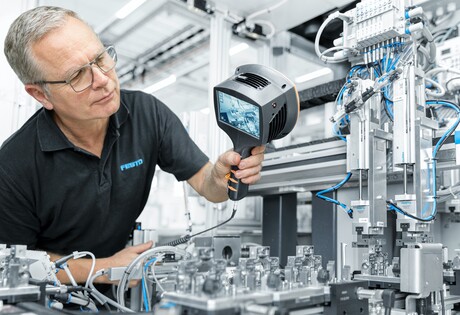

Festo has announced a compressed air audit and energy-saving consulting service, Festo Energy Saving Services to DIN EN ISO 11011, in which the company’s energy efficiency experts work with customers and users to identify potential savings in how compressed air is used overall and reveal solutions to reduce consumption.

The compressed air energy efficiency audit from Festo is put forward as a starting point for users who want to increase the energy efficiency of their complete compressed air system and reduce CO2 emissions, but do not really know where to start. The consultants from Festo identify weak spots and point out those measures that are most likely to pay off for the user’s compressed air system.

The audit consists of five steps. In the first three steps, the consultants analyse the compressed air generation, compressed air preparation and compressed air distribution of the entire system. They then turn their attention to the pneumatic applications, ie, the machines and systems themselves. They analyse the energy efficiency of these machines and systems and detect any leaks. They check whether drives, valves and tubing are optimally sized, whether blowing and vacuum applications are efficiently designed and whether installation and control concepts should be optimised. In the fifth and final step, the specialists design a concept for a compressed air monitoring system with which the energy states can be permanently monitored.

At the end of the process, the user gets a detailed report with accurately documented data and recommendations for action weighted by priority. Among other things, the documentation sets out the energy consumption and costs, power reserves and CO2 emission values that many companies need to state in their sustainability report in accordance with GRI or GHG for example.

In addition, the company can provide its Festo Automation Experience — an AI-based tool for permanently monitoring the energy efficiency of a machine or system and continuously taking corrective action if deviations from the setpoint values cause energy consumption to increase. Festo says it is an easy-to-use solution that leverages AI and machine learning to help the user extract maximum value from the data produced by the machines and systems, to not only increase productivity, but also reduce energy costs.

SPP Pumps and Rodelta partner to improve safety-critical applications

SPP Pumps has announced a strategic alliance with Netherlands-based Rodelta, a manufacturer of...

KAESER Australia opens new facility in Victoria

KAESER'S new $15 million facility in Dandenong South features various innovations that echo...

Boge takes over INMATEC GaseTechnologie

With its takeover of INMATEC, Boge says its customers will be able to choose from an even wider...