Industry 4.0: A new era

By Martin Krueger, Rainer Drath, Heiko Koziolek, Zied Ouertani, ABB Corporate Research

Monday, 06 April, 2015

A new era of industrial innovation is upon us. Referred to as the fourth industrial revolution, the deeper meshing of the digital world with the world of machines holds the potential to bring about a profound transformation of industry worldwide.

The world is on the threshold of another industrial revolution - this one a result of the convergence of the global industrial system with the power of advanced computing, analytics, low-cost sensing and new levels of connectivity permitted by the internet.

The industrial revolution began when manual labour was replaced with mechanical power, starting late in the 18th century with the invention of the mechanical loom.

This revolution continued to develop in stages over the next 150 years, with further mechanisations and through the combination of steam and water power. The second stage dates to the emergence of electrification and automation. At every stage, productivity accelerated sharply beyond that stage which had preceded it.

The third, and most recent, industrial revolution stage began in 1969 with the first digital and freely programmable control systems, which replaced the traditional hardwiring of analog logic and control programs. This stage built the foundation of today’s automation pyramid and modern process control systems and has continued right up to the present day. An overview of these industrial revolutions is presented in Figure 1.

The next industrial stage

The arrival of the internet in the consumer world in the 1990s brought unprecedented change to daily life: social networks, online TV and almost instant access to huge amounts of information.

A similar revolution is now expected in industry, as government and industrial consortiums around the world see a trend of increased utilisation of internet technology in industrial production systems. Devices in the production environment are increasingly being (wirelessly) connected to each other and a network - whether a private network or the internet. Eventually industrial production systems will be capable of autonomously exchanging information, triggering actions and controlling each other more independently.

The working groups developing this new concept are widely diverse, so the description of the concept, and even its name, varies. For example, the name Industry (Industrie in German) 4.0 was conceived by a German-led working group, while in the United States a similar initiative is called Industrial Internet1,2. Both initiatives are based on technologies associated with the Internet of Things (the ubiquitous connection of all devices to the internet) and cyber-physical systems, a combination of physical objects and software systems. The initiatives mark efforts aiming to prepare global industry for what is expected to come.

Technical drivers for Industry 4.0

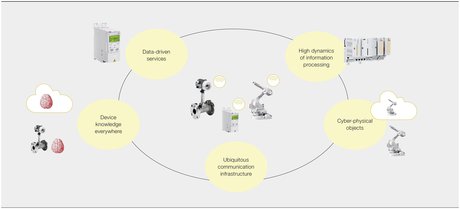

A number of technical developments are driving the efforts of Industry 4.03 (see Figure 2). Communication infrastructure will become ubiquitous throughout industrial production facilities as it becomes cheaper and readily available. This network availability builds the basis for tasks such as data acquisition, engineering, operation, maintenance and advanced services.

Once a network is in place, more devices, machines, facilities and plants will be connected, either on the internet or on a private company network. All connected physical objects will be represented by data objects in the network. As a result, these data objects form a second virtual identity within the cyber-world, the cyber-physical objects. These objects will be easy to locate, explore and analyse and will hold information about their functionality as well as their requirements.

Devices, machines, facilities and plants will be able to store knowledge about themselves beyond the physical representation and directly at the data object in the network. Each will publish updates on their current status, history, related documentation or technical requirements in the network. Such information can then easily be updated by the device’s owner, service technician or parent system.

As part of a cyber-physical system, intelligent algorithms and embedded software will be able to explore these new data sets to generate value-added services that would not have been feasible or economical before (Figure 3). This field is a topic of ongoing research4, but, from today’s perspective, remote or data-driven services mark the first steps toward these new services.

The increasing level of integration of cyber-physical objects in an internet-technology-enabled network will inevitably lead to higher levels of information processing. This will then open new doors for widely known concepts from the consumer market to enter the business-to-business market, such as plug-and-play (like plugging a USB mouse into a computer, with drivers being automatically downloaded from the web and always kept up to date) or plug-and-produce (such as exchanging an old device with an equivalent new one which then functions automatically, without the need for manual engineering, commissioning or servicing).

Cyber-physical systems have been present in the business-to-consumer market for some time. One application of the concept is the purchasing of fuel by consumers from German petrol stations. Fuel prices are submitted to a central data repository, where all stations are represented as data objects in the network. The value of isolated data objects alone is minimal. However, with the advances of mobile technologies and smartphone applications, millions of users can now make informed decisions for purchasing fuel by consulting the current prices at their individual locations. In this example, the architecture of the cyber-physical system breaks down in the following way: the physical object (petrol station), the cyber part (the data object with prices) and the software layer (the smartphone apps).

Industrial demands

The introduction of communication and internet technologies into industrial production has tremendous potential to increase productivity and flexibility, but it also raises concerns - in particular for plant owners, who combine investments, know-how, production capabilities and profit in their plants. Among the current visions of Industry 4.0, the value propositions still need to be identified. To create a sustainable acceptance of the next industrial revolution, some practical requirements need to be fulfilled:

- In order to protect investments, new technology needs to be incrementally introduced into existing production facilities, making sure not to disrupt the existing machines and technology.

- To maintain stability internet technologies must not disrupt production, neither through network outages nor through intended remote access to assets.

- The access to plant-specific data must be carefully controlled by the plant operator. Write access to production-relevant assets, machines and facilities needs an additional audit to cross-check the validity of the intervention in the context of the running production.

- As always, security is a vital aspect. Unauthorised access to data and services needs to be prevented to ensure information security and to control critical aspects of the production facilities.

Furthermore, production systems in general have stronger requirements on non-functional properties - such as availability, real-time capability, reliability, robustness, life cycle, productivity and cost - compared with IT systems in other markets.

Integration topology

To facilitate the further development of Industry 4.0 an integration topology has been adopted by the German Industry 4.0 initiative5, initially developed by ABB. The topology will allow an incremental introduction of new technology and production processes.

The core of the integration topology is the separation of the established production network from the new Industry 4.0 network (Figure 4). From the technical aspect, the separation can be implemented by either physically separated networks or logically separated networks within existing ethernet-based networks. As shown in Figure 4, the green production network symbolises an automation system that fulfils the industrial requirements on availability, reliability, sustainability and security. The yellow Industry 4.0 network enables new services and provides added value to the user. The production is not dependent on the Industry 4.0 network; therefore, failures of the network will not interrupt production.

In the first step of an implementation of the topology, assets, devices, production lines and factories are connected to the Industry 4.0 network with read-only access (yellow markers). Authenticated participants can read, for example, device IDs, diagnostic data, parameters or production data. This data will form the foundation of future Industry 4.0 value-creation processes. In a second step, write access will be introduced with an approval instance to avoid unintended effects on the running production.

The data of the yellow Industry 4.0 network is collected in a private, secure storage system. Access to this data is controlled by the data owner, ie, the plant operator. Publication of this data to the Industry 4.0 services system is controlled by interfaces and permission systems. Added value can be created - either by services within the private data system, or through third-party services within the Industry 4.0 services system.

This integration topology addresses the industrial requirements of investment protection, system stability, controllability and data security issues. The German Industry 4.0 steering committee has published this topology under the Industry 4.0 umbrella5.

What is needed

Many components comprising the fourth industrial revolution are not new. Cloud technology, network devices, communication interfaces and data-driven services are well established in many markets. However, in order for the next stage to move forward, a number of agreements and principles need to be established, such as:

- Cross-vendor agreement of standardised syntax and semantics to identify, collect and store data;

- Cross-vendor agreement of standardised services based on standardised interfaces, communication and semantics;

- Introduction of principles such as (for example) self-exploration or plug-and-explore to facilitate cross-vendor value creation;

- Availability of services to create added value from the cross-vendor availability of data;

- Interlinking of services with other third-party services;

- Availability of data throughout the value chain and supply chains in real time;

- Dynamic, partly autonomous adaptation of production services to changes in environmental parameters (such as plug-and-produce for replacement devices or update of software during continued production);

- Reorganisation of production processes to systematically exploit data and services.

This new industrial revolution is a phenomenon that will flourish. The key to bringing added value to the customer lies in better understanding the requirements for standardisation enabling the interaction of Industry 4.0 technologies. It is also important to investigate application cases in different industrial ecosystems to confirm the potential of the trend5.

References

- Evans PC, Annunziata M, 2012, Industrial Internet: Pushing the Boundaries of Minds and Machines, white paper, General Electric.

- Kagermann H et al, 2013, Recommendations for implementing the strategic initiative Industry 4.0, technical report, acatech, 2013.

- Drath R, Horch A, 2014, Industry 4.0: Hit or Hype?, IEEE Industrial Electronics Magazine 8(2), pp 56-58.

- Kagermann H et al, 2014, Smart Service World: Recommendations for the Strategic Initiative Web-based Services for Businesses, technical report, acatech, 2014.

- Platform Industry 4.0, 2014, Exemplarische Integrationstopologie, available: http://www.plattform-i40.de/sites/default/files/I40 - Exemplarische Integrationstopologie.pdf

IO-Link and the role of the IO-Link Master

While it is true that IO-Link is plug-and-play from a hardware perspective, it pays to do your...

Security enhanced for digitalised industrial boilers

Industrial boiler maker Bosch Industriekessel depends on secure gateway technology to offer...

Mineral processing: a eulogy for analog

Leading mines have already accomplished an automated, digitally connected mine and are reaping...