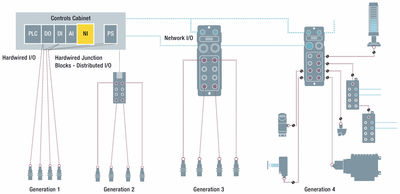

Four generations of I/O integration

Over the years, technology has improved in the routing and terminating of I/O, increasing efficiency and productivity for machine builders.

For machine builders, historically the only cost-effective method for terminating I/O from sensors, actuators, valves and devices was to route all connections into the control cabinet and terminate them there. Over the years, technologies have been developed to improve the routing and terminating of I/O to increase efficiency and productivity for machine builders.

A laborious and time-consuming start

The first generation of I/O integration philosophy relied heavily on centralised control architectures and the traditional laborious, time-consuming method of technicians performing all wiring and terminating of the many individual leads into the control panel. Terminating wires is a tedious process that includes routing long cable runs from sensors and devices to the control cabinet terminals, then shielding, cutting, stripping, ferruling, labelling, crimping and terminating the hundreds of wires.

Typically, for experts this procedure takes about 7–10 minutes per wire. With this method, 100 terminations would take approximately 12 hours — equating to approximately $700–$1000 in labour costs. And when you include the statistical probability of approximately 10–15% for human error, there is the accompanying additional cost of debugging wiring errors and reworking. Adding sensors or valves requires reworking as well, while the variety of cord sets required for sensors, actuators, valves and devices adds overhead and inventory costs.

In this first-generation control architecture it is helpful to picture separate ‘slices’ of I/O components connected and terminated in the PLC control cabinet. In a typical application, the communication head and the power supply sit on the left-hand side of the backplane bus and are followed along the backplane by the CPU, communication control I/O, individual I/O devices such as discrete 24 V input cards or 0-10 V analog cards, digital device I/O, valve manifold control I/O, RFID control I/O and specialty device control I/O. Usually, a limited number of slots are available in the backplane where individual slices of I/O control components can be inserted.

The addition of passive junction boxes

In the second generation of I/O integration, passive junction boxes were added to the architecture. These boxes help shorten cable runs from sensors to the junction box, but they do not reduce the number of terminations or offer any diagnostic capabilities. While the passive junction box strategy does provide some reduction of labour time, it still fails to deliver any benefit for diagnostics or error prevention.

More choices: remote termination boxes or remote I/O blocks

The third philosophy in I/O architectures features distributed or remote I/O stations using fieldbus or network architecture. For controls architects, this presents the choice of using either remote termination boxes or remote I/O blocks with direct connections. Remote termination boxes help with distributing terminations closer to the sensors but do not help reduce the number of terminations. Therefore, this method allows for shorter cable runs and provides some diagnostic capabilities, but it also adds the cost of remote termination control panels. Using remote I/O blocks with direct connections delivers shorter cable runs, onboard diagnostics of short-circuits or overcurrent, and dramatically reduces the number of terminations. Just as importantly, it considerably reduces the need for debugging, reducing overall labour costs.

The limitation with this method is that a distributed network block typically can host 16 inputs or outputs or 4–8 analog points, or some mix thereof. Therefore, if you need a 17th input or output, you need to add another I/O block to the network. Furthermore, if you need one additional analog input or output, you need an additional block. Those are just two examples of the limitations with this method. In effect, this would entail moving the I/O slices from the control cabinet to the machine and connecting them with network nodes. The cost is very high when using this method to update a system.

IO-Link leading the way to Industry 4.0

The fourth, and latest, generation of I/O architecture is based on IO-Link technology. This technology has existed since 2006 and is now gaining rapid acceptance in the market. It is the technology enabling Industry 4.0 and the Industrial Internet of Things for the next generation of manufacturing. Each IO-Link master block typically provides up to eight IO-Link ports, and each port can host a variety of I/O. I/O hubs are child nodes that can be connected to the IO-Link master, and can act as a concentrator to capture discrete or analog I/O. Smart devices like RFID, smart sensors including those for pressure, colour, distance, or transducers and encoders can be directly connected to the IO-Link master, provided they offer an IO-Link interface. With this technology, one IO-Link master can host up to 240 I/O points with IO-Link I/O hubs, or up to 64 channels of analog I/O or eight IO-Link smart devices, or any combination thereof.

An increasing number of manufacturers are introducing new devices that are compatible with IO-Link. Many new smart IO-Link devices have been produced, such as for valve manifolds, grippers, vacuum generators, stack lights, smart lights for process visualisation and RFID systems.

Because IO-Link is a data communication technology, and not a signal transmission method, IO-Link devices offer considerable diagnostic capabilities. For instance, IO-Link devices can be configured to provide notification of events and alarm conditions, or be used for ease of maintenance and troubleshooting. Another important benefit is that IO-Link based systems require only the standard unshielded, noise-immune M12 sensor cables, which are already used throughout the previous generations’ architecture. With IP67-rated IO-Link masters, you can use moulded, quick-connect cables to avoid mis-wiring and reduce troubleshooting.

Reducing costs and downtime while improving the quality of automation

The use of IO-Link technology simplifies device connections and eliminates or reduces wiring and terminations dramatically, thus reducing machine build times. Additionally, IO-Link technology makes machines smarter by providing extended diagnostic capabilities and helps them be more adaptable to changing technologies for sensors and smart devices. IO-Link technology enables increased modularity of machines and reduces costs by using I/O hubs for enhanced high density of I/O, and standardises connectivity across the machine or the facility.

The IO-Link master block provides the interface to the higher-level controller (PLC) and controls the communication with connected IO-Link devices and backplane buses. IO-Link connects all sensors and devices by seamlessly bridging with a fieldbus or Ethernet. In a distributed modular I/O system with IO-Link, devices can be installed within a 20 m radius from the master, so I/O devices can be easily distributed across the machine while also enabling the use of smaller electrical cabinets. IO-Link’s instantaneous feedback of machine operation improves overall equipment efficiency, improves quality of automation and optimises productivity.

Highly precise and safe control of hydrogen testing

With a modular control solution from Beckhoff featuring over 500 data points, Greenlight...

Three strategies that will enable IIoT deployment

A tech insider reveals how the food and beverage industry can take small, strategic steps forward...

Meaningful connections: connectivity challenges in Australia's process automation landscape

Increased connectivity is a pivotal factor in the future of process automation across Australia,...