Edge technology: accessing and integrating critical isolated data

The truth behind the hype.

Industrial markets are talking about edge technology and the remarkable advantages it brings in implementing the IIoT and Industry 4.0. Edge has become a buzzword with many voices defining it and maintaining how it should be done. The claims have led to a lot of misconceptions as to what edge technology is, what it does and who needs it.

Does edge technology take the place of the control system?

Prospective users ask if edge technology is supposed to replace SCADA or their control system. The answer is no. Edge technology — whether edge gateways, edge devices or the new edge controllers — are complementary to control systems. They’re designed to make systems smarter. An edge device works in concert with the control system to provide access to data not currently available.

Every industrial control system connects and collects data from sensors and actuators, but there are some sensors and actuators that are not connected. These isolated production elements provide no data to the control systems and make it difficult for businesses to respond rapidly to complex problems or achieve desired business outcomes because they don’t have the whole picture. Getting data from these disparate machines that are not currently connected due to factors such as incompatibility or proprietary software is the benefit of the edge layer. The edge device takes control system data and non-control system data and integrates it, so users have one view of the entire operation and make better decisions with this holistic view of the equipment than would be possible otherwise.

If you already use PLCs or PACs, do you need edge technology?

Yes. No matter what type of control system is used, in order for users to gain access to the isolated data, the system requires edge technology. Edge technology not only allows data from isolated elements to be accessed, it also gathers data from other business or internet constructs and consolidates the information. Equally important, edge technology allows better analytics to be run at the plant level to help give meaning to the data collected. So regardless of the user’s control system, edge technology is needed to make the system smarter. But which type of technology to choose is based on system architecture and goals.

Edge gateways, edge devices and edge controllers

The primary types of edge technologies are edge gateways, edge devices, and the new edge controllers that integrate PLC/PAC and edge functions into a single box (see Figures 1 and 2).

Edge gateways would likely be sufficient if your application requires the collection of data at the machine and then offloads that data to the cloud or other higher-level computing systems for processing. Users need to do research, however, to be sure they’re not using an edge gateway where an edge device with the advantage of local processing would significantly reduce latency, improve security, reduce cloud storage costs and enhance real-time decision-making.

Edge devices allow processing at the machine level. The device is integrated with the current control system, consolidates additional IoT data from available sensors and smart devices, and is the choice in existing brownfield plants that don’t want to change control systems.

Edge controllers integrate both PLC/PAC control and edge processing into a single system. Edge controllers offer a generational advancement to PLC- and PAC-based industrial control systems by enabling safe, secure communication between real-time deterministic control and non-deterministic applications that leverage external data to analyse and optimise business operations. Edge controllers provide software-defined controls with enhanced optimisation capabilities, while maintaining the stringent reliability, safety and security required in industrial applications. The integration of control functions and edge processing makes edge controllers the obvious choice for greenfield projects. In addition, because of the controller’s other benefits, existing plants may want to evaluate an edge controller before choosing another edge device.

Advantages of edge control technology

True edge control technology is innovative and new, but is an evolutionary, rather than a revolutionary, development. While offering significant advantages, it is easy to integrate with a plant’s existing systems. Users need to be aware of edge control characteristics and benefits, so they don’t get older edge technology represented as edge control. Below are some of the capabilities of a true edge controller.

Multiple operating systems in a single box

Key to the ability to process at the edge while providing control functions is the edge controller’s integration of multiple operating systems in a single system. Enhanced non-deterministic edge processing runs on a general-purpose operating system (OS) such as Linux, in parallel with a real-time operating system (RTOS) used for deterministic control. Both systems operate on the same physical hardware. The real-time system can optimise equipment control by leveraging data and analytics supplied by the general-purpose system. The general-purpose system can also work in conjunction with external data sources such as enterprise, financial, environmental and other databases via the internet. Communication between the real-time and non-real-time systems must be highly secure to ensure that the integrity of the real-time control system is maintained. Users need to evaluate carefully to be sure the edge controller being considered has this multi-operating system capability. Both OSes need to work in a safe and cooperative manner, meaning if the general OS fails or crashes it should have no impact on the RTOS. Likewise, there is no way the applications running on the general-purpose OS can impact the determinism on the RTOS side.

Based on hypervisor technology

The technology behind a true edge controller includes a multi-core processor layered with a bare-metal hypervisor. Through the hypervisor, the multi-core hardware is managed to provide the experience of two independent controllers with a secure communication link between them. This cooperative framework allows near-real-time analytics to run in parallel with real-time deterministic control processes. The ability to run the two operating systems (an RTOS such as VxWorks and a general-purpose OS such as Linux) in tandem is an entirely new approach to the optimisation of control processes. Hypervisor technology makes it possible to run analytics and optimisation applications at the machine level without directly impacting deterministic, real-time control, assuring new levels of reliability and security.

Modern programming languages simplify analytics

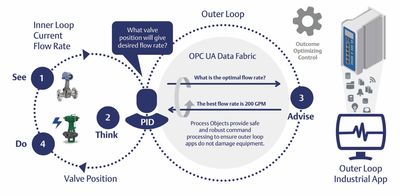

Today with current PACs, users are accustomed to creating rudimentary analytics using IEC 61131-3 languages. In contrast, advanced edge controllers can host modern programming languages, including C/C++, Java and Python, on the general-purpose OS, while supporting standard IEC 61131 languages and C on the RTOS. These and other advanced languages can be used to apply complex optimisation algorithms or analytics to operations without affecting the control process. This enables the use of an ‘outer loop’ layer in an application that can ‘advise’ the typical ‘see-think-do’ control loop, optimising the real-time control application. In case there is a disruption of some type in this outer loop, the real-time deterministic control is not affected and continues to provide the same functionality as a traditional PAC (see Figure 3).

Rapid start-up

The key advantage of edge technology is that it makes possible the collection of vital data from industrial assets whether or not this data resides in traditional PLC/PAC controllers. Traditionally, people have had to open the control logic and integrate this additional data into the PLC — an expensive and potentially disruptive step. The benefit of the edge controller is this additional data is available without modifying the PLC logic. This helps users start getting a holistic system view into the optimisation apps without having to engage the original OEM to modify the machine logic. The data collected on the edge must be cleaned and normalised into a similar structure, which simplifies app development. OPC UA has emerged as the preferred approach for data representation as it is open, secure and structured.

Rugged design

Edge controllers are, by definition, at the machine level, which greatly increases the harshness of the environment. Edge devices must be rugged enough to withstand high heat, variances in air quality and vibration — with no compromise of performance. Users should choose UL-certified devices that have been designed to work at the machine level.

Heat is a particular challenge. Edge controllers and devices require a standard operating range of -20 to 60°C. Many so-called edge devices de-rate processor performance when they cross 50°C since they aren’t created for harsh environments. This slows down operation, which is unacceptable for high-performance devices that must operate effectively at the machine level. Instead, look for heat transfer technology built into the edge controller that will maintain full performance throughout the entire temperature range.

Security

One of the keys to the data security of edge controllers is the use of the OPC UA protocol. OPC UA is a secure, platform-independent, scalable and object-oriented architecture for representing and communicating information. By using OPC UA, information can be modelled so that an application can inherently derive its meaning and consequently make better decisions based on that meaning. This enables applications to gain intelligence that can lead to new and exciting outcomes in data management. In addition, OPC UA provides a mechanism to protect the confidentiality and integrity of information and to determine whether applications are trustworthy — a fundamental need of Industry 4.0. OPC UA also allows contextualisation of data for better analytics.

Putting edge control to work in your systems

What can edge control do for industrial enterprises that they’re not able to do now? Below are a few examples.

Remote monitoring of control system health

Big industrial firms, and OEMs with large fleets or numerous remote assets, find it very difficult today to assess the health of their fleet, equipment and plants. While large SCADA systems usually provide alerts for operational alarms and events, it can be quite challenging to actually debug and diagnose issues in the field, especially in remote areas.

Incorporating edge computing concepts with a PAC makes it possible to monitor and diagnose a fleet of control systems remotely using cloud-based services, all configured in a secure manner. Access to detailed fault logs, hardware and firmware versions enables operators to debug faults remotely, reducing operational costs and unplanned downtime. It is even possible to update control systems remotely in a secure manner to fix faults, with no on-site time required.

Achieve a new level of business automation

Edge controllers facilitate the integration of a wide range of different devices and equipment by using business automation tools and standard IT communications protocols, making it possible to achieve a new level of business automation (Figure 4). Highly efficient maintenance and supply schedules can easily be set up, with notifications sent directly from the device to third-party suppliers and contractors. It’s also now possible to connect to IT, OT and cloud infrastructure directly from the control system to flatten the architecture and enable new levels of efficiency.

Gain new productivity with predictive analytics

Using an edge controller, it’s possible to gain a much higher level of efficiency and productivity by running predictive analytics on operational data and then using the results of this analysis to proactively optimise control actions. This process is akin to traditional process feedforward control where process variables are used to anticipate changes so the system can respond to the process before an error occurs, increasing efficiency. For example, automatically tuning PID loops with great precision reduces time for set-up and loop adjustments. Edge controllers provide the interface between the predictive diagnostics applications and real-time control facilitating the feedback loop that allows advanced analytics to dynamically improve process operations in a safe and secure manner.

Integrated voice assisted human-machine interface

Voice assistants are increasingly gaining adoption in the consumer market, and edge controls provide a secure strategy to incorporate voice assistance into HMIs. Using a third-party IoT kit such as Amazon’s AWS IoT Greengrass, edge controllers can be integrated quite easily with voice assistants such as Amazon Alexa. This kind of technology can be used alongside HMI visualisation systems in a secure manner, providing productivity gains in industrial settings by reducing training and troubleshooting time.

Highly precise and safe control of hydrogen testing

With a modular control solution from Beckhoff featuring over 500 data points, Greenlight...

Three strategies that will enable IIoT deployment

A tech insider reveals how the food and beverage industry can take small, strategic steps forward...

Meaningful connections: connectivity challenges in Australia's process automation landscape

Increased connectivity is a pivotal factor in the future of process automation across Australia,...