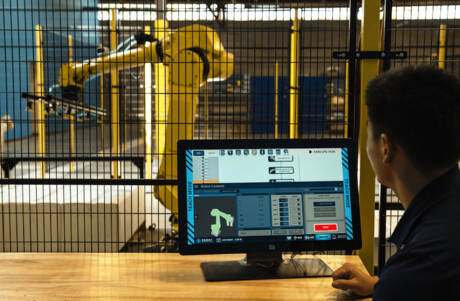

Startup making robotics system design easier for non-programmers

READY Robotics, which provides the Forge/OS robot-agnostic software platform and READY.Market online marketplace, has said it wants to eliminate the need for programmers to deploy robot hardware. To that end it is offering no-code software aimed at people working in manufacturing who don’t have programming skills.

The Columbus, Ohio startup is a spinout of robotics research from Johns Hopkins University. Kel Guerin was a PhD candidate there leading this research when he partnered with Benjamin Gibbs, who was at Johns Hopkins Technology Ventures, to land funding and pursue the company, now led by Gibbs as CEO.

“There was this ‘a-ha’ moment where we figured out that we could take these types of visual languages that are very easy to understand and use them for robotics,” said Guerin, the company’s Chief Innovation Officer.

READY Robotics’ ForgeOS operating system provides a no-code environment designed to enable anyone to program any type of robot hardware or automation device. The company said it works seamlessly with plug-ins for most major robot hardware, and similar to other operating systems, like Android, it allows running third-party apps and plugins, providing an ecosystem of partners and developers working to make robots more capable.

Implementing apps in robotics allows for new capabilities to be added to a robotic system in a few clicks, improving user experience and usability. Users can install their own apps, such as Task Canvas, which provides a building block programming interface similar to Scratch, a simple block-based visual language for kids developed at MIT Media Lab, which was influential in its design.

Task Canvas allows users to show the actions of the robot, as well as all the other devices in an automation cell (such as grippers, PLCs and machine tools) as blocks in a flow chart. The user can easily create the necessary logic by tying these blocks together without writing any code.

The interface offers non-programmers a more ‘drag-and-drop’ experience for programming and deploying robots, whether working directly on the factory floor with real robots on a tablet device or with access to simulation from Isaac Sim, powered by Nvidia Omniverse.

The company is developing Omniverse Extensions — Omniverse kit applications based on Isaac Sim — and can deploy them on the cloud. It uses Omniverse Nucleus — the platform’s database and collaboration engine — in the cloud as well.

Isaac Sim is an application framework that enables simulation training for testing out robots in virtual manufacturing lines before deployment into the real world.

“Bigger companies are moving to a sim-first approach to automation because these systems cost a lot of money to install. They want to simulate them first to make sure it’s worth the investment,” Guerin said.

The startup charges users of its platform licensing per software seat and also offers support services to help roll out and develop systems. It’s a huge opportunity for READY Robotics: roughly 90% of the world’s factories haven’t yet embraced automation, which is a trillion-dollar market.

Ready Robotics is a member of Nvidia Inception, a free program that provides startups with technical training, go-to-market support and AI platform guidance. The startup operates in an ecosystem of world-leading industrial automation providers, and these global partners are actively developing integrations with platforms like Nvidia Omniverse and are investing in Ready, according to Guerin.

“Right now, we are starting to work with large enterprise customers who want to automate but they can’t find the expertise to do it,” he said.

The company also runs Ready Academy, which offers a catalogue of free training for manufacturing professionals to learn the skills to design, deploy, manage and troubleshoot robotic automation systems.

“For potential customers interested in our technology, being able to try it out with a robot simulated in Omniverse before they get their hands on the real thing — that’s something we’re really excited about,” Guerin said.

Schneider Electric signs Motion Solutions as ANZ cobot distributor

Motion Solutions Australia and Motion Solutions New Zealand have been appointed as Schneider...

Top 5 robotics trends for 2025

The International Federation of Robotics has identified five key trends in robotics for 2025.

ARM Hub offers NVIDIA access for Propel-AIR participants

Robotics companies are invited to access NVIDIA AI and robotics tech through the Propel-AIR...