Spider worker robots of the future developed

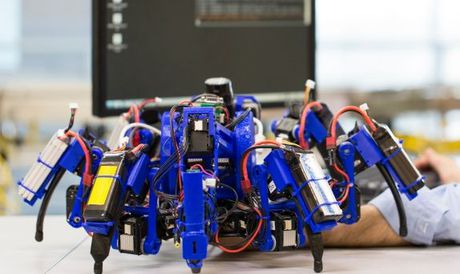

Siemens researchers in Princeton, New Jersey, have developed prototype spider-like robots called ‘SiSpis’ that can work collaboratively to print structures and surfaces.

“SiSpis are part of a larger picture that we define as Siemens Agile Manufacturing Systems, and they represent the core of our autonomous systems research here in Princeton,” said Livio Dalloro, who heads the Product Design, Modeling and Simulation Research group in the Automation and Control Technology Field at Siemens Corporate Technology. “We are looking at using multiple autonomous robots for collaborative additive manufacturing of structures, such as car bodies, the hulls of ships and airplane fuselages.”

Dalloro says that the spider-like bots are essentially fully autonomous additive manufacturing devices with legs. Each spider is equipped with an extruder similar to those on traditional 3D printers, but is limited — for now — to using a cornstarch-and-sugarcane printing substance known as polylactic acid.

Of course, adding a layer of material to the inner surface of something the size of a ship’s hull is a job that would require many spiders.

“Each spider is capable of manufacturing only a small portion of a work piece,” explained Hasan Sinan Bank, who has played a leading role in the project. “We are therefore trying to conceptualise and optimise the kinds of collaboration these robots should engage in.” This process is supported by algorithms developed by Dalloro’s team that allow multirobot task planning so that two or more devices can collaborate on the additive manufacture or surface processing of a single object or area.

The robots use onboard cameras as well as a laser scanner to interpret their immediate environment. Knowing the range of its 3D-printer arm, each robot autonomously works out which part of an area it can cover, while other robots use the same technique to cover adjacent areas.

The spiders autonomously know where they are in a given environment. When its batteries are low after about two hours, a spider will find its way back to a charging station, but not without first transmitting its data to another spider that has just been charged, thus allowing the second spider to pick up exactly where the first one left off.

Siemens’ spider-worker project was initiated in January 2014. “Its goal,” said Dalloro, “was to create a prototype platform for autonomous manufacturing machines that can understand a task, split it up among available robots and enter into a manufacturing process in a collaborative and coordinated way without explicit programming.”

China to invest 1 trillion yuan in robotics and high-tech industries

China's National People's Congress has announced a venture capital fund to expand...

Schneider Electric signs Motion Solutions as ANZ cobot distributor

Motion Solutions Australia and Motion Solutions New Zealand have been appointed as Schneider...

Top 5 robotics trends for 2025

The International Federation of Robotics has identified five key trends in robotics for 2025.