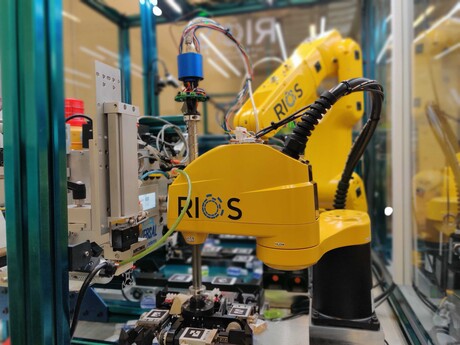

RIOS to bring AI-based robotics and automation to Australia

US company RIOS Intelligent Machines, which creates end-to-end AI-powered robotic work cells for factory automation, has announced that it has raised AU$39 million in Series A funding led by Main Sequence, the deep-tech fund founded by CSIRO. The new capital will be used to deploy its robotic fleet at scale to both new and existing customers, and to establish operations in Australia.

The oversubscribed round includes new major investors Yamaha Motor Ventures, Orbit Venture Partners, Hypertherm Ventures, and strong participation from existing investors Morpheus Ventures, Grit Ventures, Valley Capital Partners and others.

Main Sequence Partner Mike Zimmerman will join RIOS’s board of directors, and Yamaha Motor Ventures COO and Managing Director Anish Patel has joined as a board observer.

RIOS helps enterprises automate their factory assembly lines, warehouses or supply chain operations by deploying its AI-powered robotic work cells on the factory floor. Its robotic work cells are currently deployed in the United States in the manufacturing, consumer packaged goods, and food & beverage sectors. RIOS pioneered the robots-as-a-service (RaaS) business model for robotic work cells well before other automation providers, and currently offers its robotic workforce through a factory automation-as-a-service agreement, in which customers have no upfront capital commitments. The company has signed agreements with over a dozen customers in the US and Japan, from mid-sized businesses to large enterprises.

“With the global economy set to double by 2040, we need to supercharge our planet’s industrial productivity, modernising manufacturing and applying advanced technologies such as AI and robotics to improve output,” said lead investor Mike Zimmerman. “RIOS’s combination of RaaS business model and adaptable end-to-end robotic work cell platform is the ideal answer to the labour and supply chain challenges facing manufacturers around the globe. Having looked at a wide range of robotics technologies and services, Main Sequence was attracted to RIOS’s strong market traction, positive customer feedback, and world-class team.

“We’re also thrilled that RIOS is strategically tapping into Australia’s ecosystem of industry experts, research institutions, and commercial companies to both commercialise innovative robotic technologies and get early access to the Australian market.”

Main Sequence’s investment in RIOS is also aligned with Australia’s Modern Manufacturing Strategy, which lays out how Australia can establish a more competitive and resilient manufacturing sector. Key pillars of this strategy include backing digital transformation and establishing supply chain resilience, both of which are core capabilities for RIOS, especially in the food and beverage sector which is also an Australian National Manufacturing Priority.

RIOS focuses on the last frontier of automation in factories, in which traditional automation breaks down. It says it has built a new breed of robots possessing higher levels of dexterity, cognitive skills, and autonomy, which are geared up to tackle hard-to-automate tasks in unstructured environments. Today, the company has engineered sophisticated hardware and software/AI platforms in the robotics space, which includes human-like tactile sensors for robots, a haptics intelligence platform, and highest performance end-of-arm tooling.

“Bedrock sectors of our global economy are crippled by a labour shortage problem that COVID-19 turned into a full-blown crisis,” said Dr Bernard Casse, RIOS’s CEO. “Today, most factories in the world are labour-intensive, and with millions of jobs unfilled, manufacturers are unable to keep up with skyrocketing consumer demand.

“We have the cure to this trillion-dollar opportunity. We’re re-industrialising these industries with best-in-class technology while upskilling our workforce in the process and enabling them to access higher-level and better-paying jobs.”

RIOS says its value proposition to its customers is production-grade machines that meet throughputs and KPIs, are easy to use, have practically zero downtime, and can be integrated within their existing workflows.

China to invest 1 trillion yuan in robotics and high-tech industries

China's National People's Congress has announced a venture capital fund to expand...

Schneider Electric signs Motion Solutions as ANZ cobot distributor

Motion Solutions Australia and Motion Solutions New Zealand have been appointed as Schneider...

Top 5 robotics trends for 2025

The International Federation of Robotics has identified five key trends in robotics for 2025.