Compact 3D lidar system could make autonomous motion safer

Researchers in Japan have developed a new non-mechanical 3D lidar system that is the size of a business card and is the first time that the capabilities of conventional beam-scanning lidar systems have been combined with those of a newer 3D approach known as flash lidar.

In the research published in Optica, investigators led by Susumu Noda from Kyoto University in Japan describe their new non-mechanical 3D lidar system and show that it can be used to measure the distance of poorly reflective objects and automatically track the motion of these objects — overcoming some of current lidar technology’s limitations.

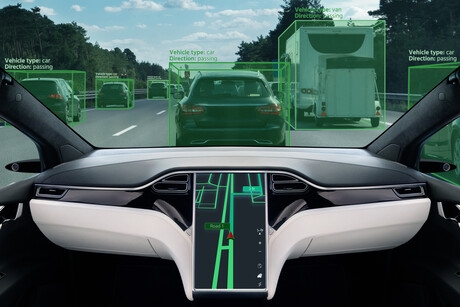

“With our lidar system, robots and vehicles will be able to reliably and safely navigate dynamic environments without losing sight of poorly reflective objects such as black metallic cars,” Noda said. “Incorporating this technology into cars, for example, would make autonomous driving safer.”

The new system is possible due to a unique light source the researchers developed called a dually modulated photonic-crystal laser (DM-PCSEL). Because this light source is chip-based it could eventually enable the development of an on-chip all-solid-state 3D lidar system.

“The DM-PCSEL integrates non-mechanical, electronically controlled beam scanning with flash illumination used in flash lidar to acquire a full 3D image with a single flash of light,” Noda said. “This source allows us to achieve both flash and scanning illumination without any moving parts or bulky external optical elements, such as lenses and diffractive optical elements.”

Combining scanning and flash illumination

Lidar systems map objects within view by illuminating those objects with laser beams and then calculating the distance of those objects by measuring the beams’ time of flight (ToF) — the time it takes for the light to travel to objects, be reflected and then return to the system. Most lidar systems in use and under development rely on moving parts such as motors to scan the laser beam, making these systems bulky, expensive and unreliable.

One non-mechanical approach, known as flash lidar, simultaneously illuminates and evaluates the distances of all objects in the field of view with a single broad, diffuse beam of light. However, flash lidar systems can’t be used to measure the distances of poorly reflective objects like black metallic cars due to the very small amount of light reflected from these objects. These systems also tend to be large because of the external lenses and optical elements needed to create the flash beam.

To address these critical limitations, the researchers developed the DM-PCSEL light source. It has both a flash source that can illuminate a wide 30°×30° field of view and a beam-scanning source that provides spot illumination with 100 narrow laser beams.

They incorporated the DM-PCSEL into a 3D lidar system, which allowed them to measure the distances of many objects simultaneously using wide flash illumination while also selectively illuminating poorly reflective objects with a more concentrated beam of light. The researchers also installed a ToF camera to perform distance measurements and developed software that enables automatic tracking of the motion of poorly reflective objects using beam-scanning illumination.

Measuring objects with varying reflectivity

“Our DM-PCSEL-based 3D lidar system lets us range highly reflective and poorly reflective objects simultaneously,” Noda said. “The lasers, ToF camera and all associated components required to operate the system were assembled in a compact manner, resulting in a total system footprint that is smaller than a business card.”

The researchers demonstrated the new lidar system by using it to measure the distances of poorly reflective objects placed on a table in a lab. They also showed that the system can automatically recognise poorly reflective objects and track their movement using selective illumination.

The researchers are now working to demonstrate the system in practical applications, such as the autonomous movement of robots and vehicles. They also want to see if replacing the ToF camera with a more optically sensitive single-photon avalanche photodiode array would allow the measurement of objects across even longer distances.

Schneider Electric signs Motion Solutions as ANZ cobot distributor

Motion Solutions Australia and Motion Solutions New Zealand have been appointed as Schneider...

Top 5 robotics trends for 2025

The International Federation of Robotics has identified five key trends in robotics for 2025.

ARM Hub offers NVIDIA access for Propel-AIR participants

Robotics companies are invited to access NVIDIA AI and robotics tech through the Propel-AIR...