An automated way to assemble thousands of objects

The manufacturing industry (largely) welcomed artificial intelligence with open arms. However, planning for mechanical assemblies still requires more than scratching out some sketches — it’s a complex conundrum that means dealing with arbitrary 3D shapes and highly constrained motion required for real-world assemblies.

Human engineers need to manually design assembly plans and instructions before sending the parts to assembly lines, and this manual nature translates to high labour costs and the potential for error.

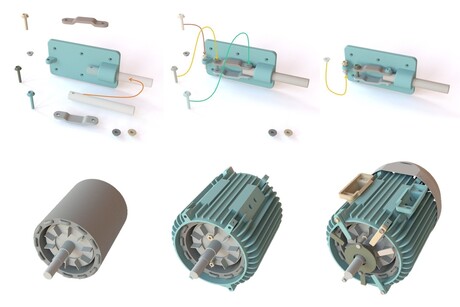

In a quest to ease some of these burdens, researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), Autodesk Research and Texas A&M University came up with a method to automatically assemble products that’s accurate, efficient and generalisable to a wide range of complex real-world assemblies. Their algorithm efficiently determines the order for multipart assembly and then searches for a physically realistic motion path for each step.

The team created up a Spartan-level large-scale dataset with thousands of physically valid industrial assemblies and motions to test their method. The proposed method is capable of solving almost all of them, especially outperforming previous methods by a large margin on rotational assemblies, like screws and puzzles. It can solve 80-part assemblies within several minutes.

“Instead of one assembly line specifically designed for one specific product, if we can automatically figure out ways to sequence and move, we can use a fully adaptive setup,” said Yunsheng Tian, a PhD student at MIT CSAIL and lead author on the paper. “Maybe one assembly line can be used for tons of different products. We think of this as low-volume, high-mixed assembly, opposed to traditional high-volume, low-mixed assembly, which is very specific to a certain product.”

Given the objective of assembling a screw attached to a rod, for example, the algorithm would find the assembly strategy through two stages: disassembly and assembly. The disassembly planning algorithm searches for a collision-free path to disassemble the screw from the rod. Using physics-based simulation, the algorithm applies different forces to the screw and observes the movement. As a result, a torque rotating along the rod’s central axis moves the screw to the end of the rod, then a straight force pointing away from the rod separates the screw and the rod. In the assembly stage, the algorithm reverses the disassembly path to get an assembly solution from individual parts.

“Think about IKEA furniture — it has step-by-step instructions with the little white book. All of those have to be manually authored by people today, so now we can figure out how to make those assembly instructions,” said Karl DD Willis, a senior research manager at Autodesk Research. “You can imagine how, for people designing products, this could be helpful for building up those types of instructions. Either it’s for people, as in laying out these assembly plans, or it could be for some kind of robotic system right down the line.”

The disassembly/assembly dance

With current manufacturing, in a factory or assembly line, everything is typically hard-coded. If you want to assemble a given product, you have to precisely control or program instructions to assemble or disassemble a product. Which part should be assembled first? Which part should be assembled next? And how are you going to assemble this?

Previous attempts have been mostly limited to simple assembly paths, like a very straight translation of parts — nothing too complicated. To move beyond this, the team used a physics-based simulator — a tool commonly used to train robots and self-driving cars — to guide the search for assembly paths, which makes things much easier and more generalisable.

“Let’s say you want to disassemble a washer from the shaft, which is very tightly geometrically assembled. The status quo would simply try to sample a bunch of different ways to separate them, and it’s very possible you can’t create a simple path that’s perfectly collision-free,” Tian said. “Using physics, you don’t have this limitation. You can try, for example, adding a simple downward force, and the simulator will find the correct motion to disassemble the washer from the shaft.”

While the system handled rigid objects with ease, it remains in future work to plan for soft, deformable assemblies.

One avenue of work the team is looking to explore is making a physical robotic set-up to assemble items. This would require more work in terms of robotic control and planning to be integrated with the team’s system, as a step towards their broader goal: to make an assembly line that can adaptively assemble everything without humans.

“The long-term vision here is, how do you take any object in the world and be able to either put that together from the parts, using automation and robotics?” Willis said. “Inversely, how do we take any object in the world that’s made up of many different types of materials and pull it apart so that we can recycle and get them into the correct waste streams? The step we’re taking is looking at how we can use some advanced simulation to be able to begin to pull apart those parts, and eventually get to the point where we can test that in the real world.”

“Assembly is a longstanding challenge in the robotics, manufacturing and graphics communities,” said Yashraj Narang, senior robotics research scientist at NVIDIA. “This work is an important step forward in simulating mechanical assemblies and solving assembly planning problems. It proposes a method that is a clever combination of solving the computationally simpler disassembly problem, using force-based actions in a custom simulator for contact-rich physics, and using a progressively deepening search algorithm. Impressively, the method can discover an assembly plan for a 50-part engine in a few minutes.”

China to invest 1 trillion yuan in robotics and high-tech industries

China's National People's Congress has announced a venture capital fund to expand...

Schneider Electric signs Motion Solutions as ANZ cobot distributor

Motion Solutions Australia and Motion Solutions New Zealand have been appointed as Schneider...

Top 5 robotics trends for 2025

The International Federation of Robotics has identified five key trends in robotics for 2025.