The new industrial revolution: robots are an opportunity, not a threat

If robots and AI are our future, we need to embrace the technology and work out how best to collaborate and make it work for everyone.

Invasion. Takeover. These are the kind of words that have been bandied about in news headlines about robotics and artificial intelligence in the last few years. The coverage has been almost relentlessly negative, focusing on the threat to jobs, squeezing out the human component. While such potential is there, if robotics and AI do become a threat, then we believe this would be a threat of society’s own choosing.

The market impact of robotics and autonomous systems is estimated to be US$9.8 to US$19.3 trillion a year by 2025, but a recent report from the Sutton Trust stressed concerns that this could lead to a two-tier society with:

An elite high-skilled group dominating the higher echelon of society and a lower-skilled, low-income group with limited prospects of up-skilling and hence upward mobility, resulting in a broken social ladder.

Technical innovation has always had an impact on the status quo and stirred fears of what change might bring. Currently the fear is that the owners of the means of production will become rich, while other will see their jobs and livelihoods taken by robots.

Living in a connected era

The revolution in robotics and autonomous systems has already begun. We live in a connected era where affordable technology interacts with us and with other natural and physical assets in our environment, turning data into information for a global audience.

AI has the ability to bring expert knowledge to the lay person remotely, that is, anywhere in the world, and support them in their endeavours like a virtual mentor, customising information in a useable format they can engage with. And by giving people this knowledge it offers unprecedented opportunities ranging from garden shed innovators gaining access to manufacturing processes which would previously been beyond their reach, to the potential for wealth creation in countries that are most in need of it.

For example, AI is helping communities in developing nations implement local renewable energy systems by providing intelligent automation and monitoring – almost like an online “doctor”, making sure the system is “healthy” and working properly. This means communities not only gain access to affordable and sustainable energy but can also engage in trading of any surplus energy to other consumers or utility companies.

But to achieve these benefits society has to be ready to grasp them. Governments, business and academia all have a responsibility to prepare the current and future workforce for the imminent and dramatic changes to come, and society as a whole has to buy into this new industrial revolution.

Contrary to the perceived apocalyptic scenario, we believe the future is all about people: after all, the value of technologies is in the knowledge we humans embed within them and how we interact with them, not the machines themselves. For that human-based scenario to work we need an agile, future-ready workforce, ready to embrace a data-driven world in partnership with robotics and autonomous systems.

An existing example is the Siemens “lights out” manufacturing plant in Amberg, Germany, which is automated to the point where some lines can run unsupervised for several weeks. This is viewed as a stepping stone towards a fully self-organising factory that would allow the manufacture of highly customisable products. Yet this automated factory has 1,150 employees supporting it, just with different roles focused on programming, monitoring and machine maintenance.

The new industrial revolution

Since the first industrial revolution people have generally had to follow the technology, moving to the big cities or from developing nations to developed countries, to improve their access to the opportunities offered by technology.

At Heriot-Watt we are embracing both the newest technological opportunities and the challenges that they bring. Our work involves engaging with government and industry around a people first ethos via our Centre of Embedded Innovation (CEI) concept, which is reaching out to all of our communities to enable access to the latest advances in data analysis, robotics and autonomous systems.

Studies by the Sutton Trust have indicated that in the past decade in the UK, the gap between rich and poor in society has increased, with inequality now at a record high. The CEI seeks to address this societal imbalance through making opportunity more equal, in which education plays the key role, and helping to create a new “embedded” industrial revolution which supports business and economic growth, transferring knowledge and resources to those communities most at risk of poverty.

Wealth creation and innovation must be centred on people to achieve a prosperous future that is inclusive throughout society. It’s also clear that the speed of this industrial revolution warrants a transformative change in strategy through government, industry and academia.

Wealth creation and innovation must be centred on people to achieve a prosperous future that is inclusive throughout society. It’s also clear that the speed of this industrial revolution warrants a transformative change in strategy through government, industry and academia.

This article was originally published on The Conversation. Read the original article.

Originally published here.

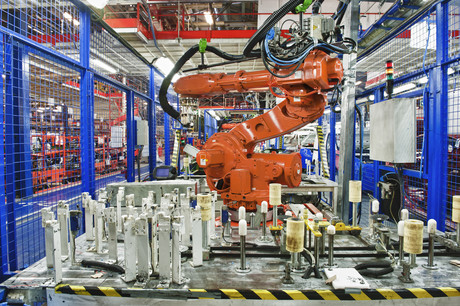

Advanced robotics in tomorrow's factory

Addressing the production challenges of complexity, customisation and openness.

Cracking the nut: robotic automation at Freedom Fresh

SCARA robots from Shibaura Machine have found a place in helping to package macadamia nuts.

Food plant expansion sustained by central robotic palletising system

A palletising system with eight robotic cells has been installed at Unilever's food factory...