Intelligent sensor technology and the cloud

Big data analytics will play an important role in the realisation of Industry 4.0, and the most efficient way to achieve it will be by the effective use of cloud computing technologies. Smart sensor technologies will therefore also play a leading role in ensuring the efficiency and accuracy of the source data.

Today we are constantly reading and hearing that the future of industrial production will be in the form of the Industrial Internet, Industry 4.0 or cyber-physical systems. The opportunity to use larger quantities of data to produce and supply goods in a more efficient and flexible way, while also saving resources and achieving better quality, ultimately depends on the reliability of the data input for the process chain — and the sensors that record real-time situations and convert these into useful data.

Of course, the management and usage of the data collected from sensors is the other large element of Industry 4.0 that needs to be considered. According to Dr Michael Gerstlauer of Teradata, we are entering “an era where sensor technology and the interconnectivity of machines — the Internet of Things — is driving the industry forward. This is an evolutionary journey of analytics capabilities that begins with today’s Agile Data Warehouse and culminates in a future state where you have a Sentient Enterprise and manufacturing processes at optimal capacity. Industry 4.0 promises new levels of process efficiency, ‘zero unplanned downtime’ of machinery, and the ability to manufacture ‘batch size 1’ — highly customised products produced at reasonable cost to the consumer.”1

Batch size 1

Perhaps the ‘holy grail’ of Industry 4.0 is the concept of a single unit batch. Smart sensor technology, coupled with adaptive automation systems, will be key to achieving this goal, in which manufacturing plants are flexible enough to adapt to individual customer requirements. Enabling high product variance in ever-smaller quantities, intelligent components (smart sensors) must be able to adapt and control themselves.

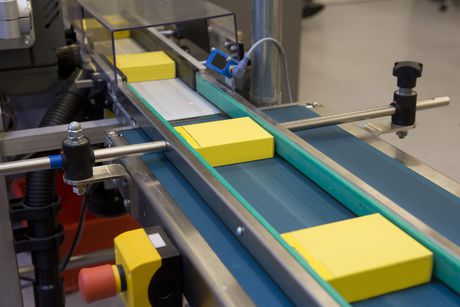

An example of a step in this direction in packaging is that it will be possible to pack items of differing sizes (such as different sized beverage bottles) on one system using smart sensor detection with automatic format adjustment. The sensors detect the change in product and signal the control system to reset itself so that the right box can be set up, the bottles can be placed inside and the box can be labelled accordingly. The system continues running automatically and does not require line shutdowns to change batches.

Smart sensor solutions, in which state-of-the-art sensor technologies are used in conjunction with integration at the control level, will provide decentralisation of certain automation functions directly in the sensor, relieving pressure on the control system and increasing machine productivity.

Perhaps the most common exemplar of the aim for batch size 1 production is an automotive production line. The sensor technology detects which assembly steps must be taken on the basis of the car body itself — thus ensuring unique identification — and guarantees continuous transparency right through to delivery. Processing steps on the object are updated via rewritable RFID transponders. RFID data cards are attached to components or integrated unseen within them. In these ways, individual vehicles can be customised ‘on the fly’ to meet a customer’s specification.

Track-and-trace transparency

The application of smart sensor technologies such as RFID, as described above, provides other benefits.

The traceability of products during complex manufacturing and logistics processes is another area of great advancement. A transparent material flow is required in production and logistics so that production decisions can be made more quickly — such as supply of parts and raw materials.

At the delivery stage, the completed product — customised for a customer — can then be identified automatically for delivery, allowing transparency and traceability monitoring right through to the customer. Future identified faults or production flaws can be traced back to individual components or production processes at a single point in time for root cause analysis, improved quality control and enhanced customer service.

Data and the cloud

Much has been said about the explosion of data that Industry 4.0 and the Internet of Things (IoT) will produce. Cloud technologies hold the promise of making the data more accessible from multiple locations, and centralising analytics.

In reality, the quantity of data generated by any given production process will depend on the nature of the process itself. In the examples above, a single car with all its RFID-identified parts may imply hundreds of data points per product, while for the bottle packaging example, there may be only one data element per product, or a few per batch.

Depending on how the data is to be used, the data may be stored and used locally, or stored and processed by a cloud service. In the case of cloud applications, local consolidation of data at the source can improve data efficiency. For example, if a particular sensor output changes only slowly or rarely, only changes need to be stored, so local consolidation comes into play. When large amounts of data are involved, local consolidation and compression can enhance efficiency significantly.

Smart sensors that incorporate their own smart logic can reduce the data demand by providing only necessary information as desired. In the bottle packaging example, the smart sensors also assist in automatically reconfiguring the process, keeping the running production data within the packaging line for best efficiency. Only final production data should need to be forwarded on for batch track-and-trace.

The cloud and intralogistics

One application where the convergence of smart sensor data and the cloud comes into its own is in the field of intralogistics. By now we all will have experienced the simple example of parcel tracking, in which we receive emails providing access to data by which we can trace the delivery of products we have purchased online. At each step of the delivery we can see where the package is, via our computers, tablets or smartphones.

In today’s intralogistics, goods are transported with a high degree of variance in content, size and weight, and at various points are weighed and measured, while having their location detected. Sensor technology identifies the goods with machine vision systems and laser-based code readers, while the volume is determined with laser scanners, light grids and encoders. Data relating to the items is scanned and uploaded to services in the cloud so that the items can be identified and compared. For example: is the parcel damaged? Is the code complete? Are the weight and volume correct? Is there a jam or has a parcel been lost?

Any defects can be tracked from all sites and any trouble spot can be identified. In addition, quality defects in the process can be identified and resolved. As the speeds on conveyors are further increased, maximum productivity is guaranteed — not just within one site, but potentially all over the world.

Smart sensor technology in this context is used to ensure high performance levels for sorting and transportation. As well as the object data, additional performance data relating to the status of the sensors, the speed of conveyors or the quality of the labels is constantly being generated.

The presentation of data at a local level can be condensed at system or factory level if necessary before being transferred to the cloud. The data delivered to the cloud by the sensors can be evaluated according to different user criteria. As described above, apps can be developed which allow the end customers to track the individual goods during the transport process on their smartphones. But it is also possible that alarm workflows can be triggered in the event of performance problems or faults, and that changes in the status of the goods will be detected in the logistics chain.

Big data that is reliable

Reliable and unambiguous identification of goods in the production process and supply chain is a vital prerequisite for efficient, autonomous control. Whether it’s a single product on a conveyor or data about millions of parcels that are transported every day, the status of all recorded data must be easy to retrieve and analyse. This is where the cloud comes into play, allowing data to be collected from multiple locations, analysed and further read and shared from still other locations.

While this data offers great opportunities, the process of preparing it in a way that allows companies to make the right decisions presents a significant challenge. This seamless flow of data and information from the sensor to the control and back again is the cornerstone of Industry 4.0.

References

1. Gerstlauer M, 2015, ‘Why You Need a Data Strategy To Succeed in Industry 4.0’, Teradata, <http://blogs.teradata.com/international/need-data-strategy-succeed-industry-4-0/>.

Performance without compromise: enhancing manufacturing quality with single-controller solutions

Most factory automation systems today have mutiple control systems that don't communicate...

From wartime wisdom to smart manufacturing: the power of condition monitoring

The shift from reactive to predictive maintenance is really a cultural transformation empowered...

Efficiency in intralogistics: AMRs and industrial 5G

How industrial 5G enhances AMR applications and performance.