ABB partners with Boliden to reduce carbon footprint of its products

ABB has announced that it is working with Boliden, the Swedish mining and smelting company, to build a strategic co-operation to use low-carbon-footprint copper in its electromagnetic stirring (EMS) equipment and high-efficiency electric motors. The aim is to reduce greenhouse gas (GHG) emissions while driving the transition to a more circular economy.

The company says the partnership with Boliden forms an integral part of its strategic ambition to reduce the environmental impact of raw materials used in its products by replacing them with lower-carbon alternatives. Apart from using recycled copper, ABB has committed to increasing the use of recycled electric steel (e-steel) and recycled aluminium. The move is also an important step in closing the circularity loop that has already seen ABB designing its motors to be up to 98% recyclable, with the remaining 2% of materials available to be incinerated for heat recovery. Recycling copper, aluminium and steel offers energy savings of between 75% and 95% compared to virgin production.

“As a part of ABB’s 2030 sustainability strategy, our target is for 80% of our products and solutions to be covered by a circularity approach. The work with Boliden is an important step towards this goal,” said Ola Norén, Head of Metallurgy Products, Process Industries, ABB. “By taking stock of the delivery by the end of this year we’ll ensure that all our metallurgy products use recycled hollow copper conductors from 2023.”

“We want to enable a more sustainable and resource-efficient future, and with this collaboration our customers can not only decarbonise by upgrading to energy-efficient motors but will also be able to install ABB technology that has an improved environmental footprint thanks to Boliden’s copper,” said Ulf Hellstrom, Managing Director at ABB Motion, Sweden. “This is an excellent example of the circular economy in practice.”

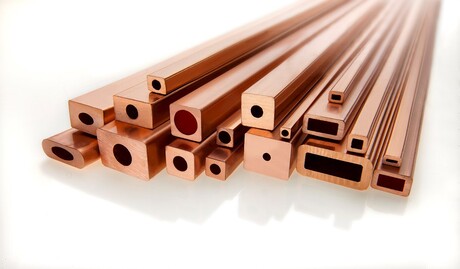

The co-operation includes ABB placing the first order for Boliden’s certified recycled copper through Finnish metals manufacturing specialist Luvata. Hollow conductor wire made from the material will be used in ABB’s EMS products for both steel and aluminium manufacturing.

As of 2023, ABB will also purchase Boliden’s low-carbon and recycled copper to cover the demand for its IE5 ultra-premium efficiency SynRM and e-mobility motors produced in Europe. The two companies have also signed a memorandum of understanding that will see ABB supporting Boliden in identifying inefficient low-voltage motors across its operating units. These motors can then be replaced with high efficiency motors within ABB’s take-back upcycling framework, with the old motors recycled to provide raw material for Boliden’s recycled copper.

Copper is a vital material for manufacturing industrial electrical equipment, but its production is energy intensive. To address this, Boliden has developed low-carbon copper that is mined using fossil-free energy and also produces copper using secondary raw material from recycled products. The carbon footprint of these products is 65% lower than the industry average. A typical 75 kW motor weighing 650 kg might include 80 kg of copper. Using Boliden’s copper saves approximately 200 kg of CO2 emissions for every one of these motors manufactured. Each stirrer has up to 2700 kg of copper, saving up to 6700 kg of CO2 per stirrer.

Ausgrid introduces Schneider Electric SF6-free switchgear

Ausgrid takes a significant step toward achieving its environmental goals with the introduction...

HRS to showcase turnkey processing solutions at APPEX 2024

HRS Heat Exchangers will be showcasing a range of turnkey line solutions for the food and...

HARTING opens production plant in Vietnam

HARTING's new 2500 m2 production site in Hai Duong, Vietnam, will manufacture the...