Signal conditioning: getting the most for your money

The importance of taking care in selecting a signal conditioner cannot be understated — a wrong choice could cost more in time and money in the future.

A variety of plant, process and instrumentation engineers, along with systems integrators, regularly face the difficult task of shopping for signal conditioners. Their goal is to obtain the highest quality conditioner for the lowest possible price. Sound simple enough? Well, it isn’t. Few of the decisions that must be made are of the black and white variety. Most involve various shades of grey. The problem is, the selection of the wrong shade can result in the purchase of inadequate equipment, or equipment that will quickly become obsolete.

Pre-purchase system planning that includes a clear definition of the system requirements is the first step in the selection process. As a minimum, you should determine sensor input, type of output, isolation needs, power requirements, physical dimensions and acceptable performance criteria.

Accuracy, linearity and repeatability

Overall system accuracy is only as good as the least accurate device in the loop. This is typically the sensor or mechanical-to-electrical interface. If the sensor, for example, is only 0.5 to 5% accurate, you probably don’t need extremely precise signal conditioning. Likewise, if your sensor is very accurate, you may not want to hinder system integrity with low-budget signal conditioners.

Accuracy, linearity and repeatability specifications are described in many different ways. Accuracy specifications should include the combined effects of repeatability, hysteresis, terminal point linearity and adjustment resolution. They should also indicate worst case or peak error of the device at the reference conditions (eg, temperature, 25°C; power, 24 VDC; and output load, 250 ohms).

If a sensor isn’t part of the device, the accuracy specification probably won’t include sensor error. Knowing the maximum combined errors of a device at reference test conditions allows you to test units against manufacturer specs, and helps estimate total system accuracy.

The terms repeatability and hysteresis reference the attributes of a conditioner output as the input is varied up and down. A conditioner output yields a different value for the same input depending on which direction it came from (due to components, transformer core losses, potentiometer shifts and so on). An accuracy specification that includes the combined effects of these two characteristics implies that the output is always (repeatable) within the stated percentage from the ideal point.

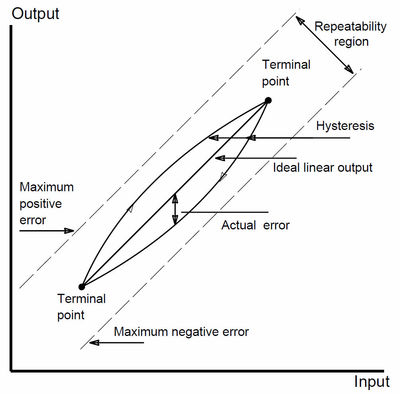

Terminal point linearity and adjustment resolution imply that a device has endpoint calibration and can be adjusted at the endpoints to within the stated specification (Figure 1). Essentially, terminal point linearity allows calculation or error E (accuracy) as a function of output span using the following equation:

A typical accuracy rating is less than ±0.1% of output span. This means that a linear conditioner, calibrated with a 1–5 VDC output (4 V span), has an output within ±4 mV from the ideal point (4 V span x 0.001). Because the accuracy specification should include repeatability and hysteresis, the output should always be within ±4 mV of the ideal. If accuracy, linearity and repeatability are specified separately, you may have to combine the individual ratings to form a complete accuracy specification.

Adjustability (zero/span)

Conditioners with adjustability can compensate for signal differences, and the ability to do so is usually worth the extra cost (typically $100). Adjustability can be accomplished in hardware or software. Some applications have no software so it must be available in hardware. In other applications involving computers, such as data acquisition and control, it isn’t possible or practical to perform all the adjustments in software, so hardware flexibility is a must. The capability to trim and calibrate hardware allows conditions to change without affecting other devices. In addition, host processors don’t get burdened, and system accuracy isn’t compromised.

For example, let’s say you are evaluating two signal conditioners. Both feature 1–5 VDC outputs and are accurate to ±0.1%of output span (4 mV). One is non-adjustable and accepts a 0–100% input and has up to a 50% span adjust capability.

After defining your requirements, you decide that the input range you are interested in is 0–50% input. The second unit will have no problem calibrating and yielding a full range output while keeping the ±0.1% accuracy rating. The first unit, however, is non-adjustable and will only yield 1–3 VDC (2 VDC span) for 0–50% input. Now, 4 mV out of a 2 VDC span is 0.2%. Hence, the first unit was not only inflexible, but turned out to be twice as inaccurate as the second.

In the real world, sensors do not necessarily provide convenient endpoint signals (eg, 0.00 mV through 50.0 mV), but approximate values such as 6.37 mV through 49.8 mV. This gives adjustable signal conditioners two advantages: they can scale a signal with inconvenient end-points and optimise performance by calibrating out errors due to the sensors or the system (eg, voltage drops, other devices and so on).

Here are a few additional advantages of signal conditioner adjustability:

- As time goes on, components age and drift. The ability to calibrate and maintain a conditioner increases its useful life.

- An adjustable conditioner also saves CPU number crunching time if you expect to make all adjustments using a software program. It eliminates the need for additional end-point calculations. Software programs are convenient for trimming and scaling. However, depending on the end points, scaling may introduce significant signal resolution and accuracy.

- The ability to adjust zero and span on the conditioner allows conditions to change without affecting other devices, burdening host processors and affecting system accuracy.

- Signal conditioner adjustability also reduces device inventory; the more flexible the unit, the less need there is to stock unique modules.

Isolation

Isolation in a signal conditioner means not having a direct electrical connection (or low impedance path) between two or more points (or circuits). The two primary components used in signal conditioners to provide isolation are transformers and optical couplers. Both devices transmit signals from one circuit to the other (via the transfer of magnetic or optical energy), and both have very high impedance paths from input to output.

There are two main reasons why you might need isolation: to break up potential ground loops and to protect equipment from high voltage surges and spikes (Figure 2).

The four possible combinations of isolation in signal conditioners include:

- Input: The input is isolated or floating from the output and power with no connection to earth ground, and the output and power share the same common. The conditioner can be connected to a grounded system, and is typically used when bringing signals in from the field to a grounded system.

- Output: The output is floating and the input and power are common with one another. It is used when sending signals from a grounded system to the field.

- Three-way (fully): Input, output and power are completely isolated from one another. Signal conditioners with full isolation can interface with three separately grounded systems.

-

Power isolation: Input and output signals are common with one another and isolated from the power common. Power or three-way isolators provide protection from power sources grounded differently than signal sources.

Once you’ve justified the need for isolation, you must determine required voltage ratings and interpret the specifications. Isolation specifications should carry two ratings: continuous and breakdown (maximum). Don’t be misled between the two when comparing technical data sheets.

Continuous refers to the amount of differential voltage (also known as common mode voltage) that can be present between the two isolated circuits on a permanent basis. Typical ratings for conventional conditioners are 250 VAC or 354 VDC.

Breakdown ratings refer to the high common mode voltages that conditioners can withstand for short durations before isolation barriers start breaking down. A common rating is 1500 VAC for one minute without breakdown, which, when properly designed and tested, will accommodate most applications.

Ratings should be in accordance with established guidelines from an accredited approval agency such as Factory Mutual (FM), Canadian Standards Association (CSA) or Underwriters Laboratories (UL). Under CSA guidelines, a conditioner claiming a continuous isolation rating more than 250 V must be tested at two times the rated voltage plus 1000 V for at least one minute without breakdown. And remember: conditioners with isolation may handle stated ratings when new, but factors such as ageing, dust build-up and general environmental wear can degrade and break down isolation barriers. In general, though, units designed, rated and tested according to established guidelines provide better lifetime performance and an additional margin of safety.

The benefits of isolation in a signal conditioner are well worth their $50–$100 extra cost. Typically, most applications need isolation when transmitting signals from one place to another. If you are not sure of the type you may need, consult an application engineer or technical support person. And when shopping in the market, ask how the ratings are achieved and verified.

Surge withstand capability

Surge withstand capability (SWC) — which is the ability of a signal conditioner to reject high voltage and frequency electrical interference — should be considered wherever signal conditioners are to be located. Typically, a unit receives a standardised high voltage (2 kV crest), decaying high frequency transient, synchronised to the line frequency (Figure 3). During testing, this signal is applied to the input/output terminals and across any isolation barriers for about 10 seconds. A conditioner with SWC protection will not be harmed by these bursts and is more reliable in the field.

RFI/EMI

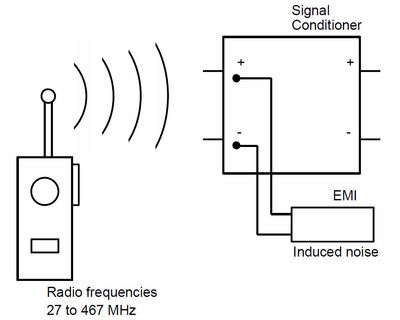

The increasing need for reliable communications in factories and plants means that more and more industrial electronic equipment may require built-in radio frequency interference (RFI) immunity. At the same time, this equipment’s susceptibility to the electromagnetic interference (EMI) effects of inductive load switching relays and noise induced by heavy operating equipment (Figure 4) must also be considered. Unfortunately, there’s a very good chance you won’t know you need RFI/EMI protection until somebody keys up a radio transmitter near your device or mounts it in a noisy electrical environment, and the output readings become erroneous.

Devices with RFI protection should specify a rejection range of frequencies at or exceeding 10 V/m field strength. Common bandwidth ranges span from 27 to upwards of 900 MHz for some portable radios.

There are two commonly used methods to reduce the effects of RFI. One is to enclose the circuit in a metal box tied to ground that has filter capacitors across the input terminals (Faraday shield). The other approach involves a combination of inductors, filter capacitors, component placement and PC board manufacturing techniques to minimise the effects of RFI.

Both approaches are valid and yield similar performance. However, the latter allows the use of durable, low-cost plastic housings instead of expensive metal enclosures. In addition, it provides the ability to remove covers and calibrate equipment in the field under RFI and EMI conditions.

Reducing the effects of RFI requires considerably more effort than EMI. RFI is transmitted to all parts of the circuitry and is easily coupled into the amplifier circuits. EMI is primarily coupled through input wiring and may be clamped and attenuated through circuit techniques.

Manufacturer testing for EMI at the output verifies the conditioner is protected from noise spikes. If you find the device lacks EMI protection, you’ll have to go the do-it-yourself route with external surge protectors or diode clamping.

Packaging

Signal conditioners come in a variety of packages including DIN rail, hockey-puck enclosures, general-purpose NEMA 1 type enclosures, NEMA 4/12 and 19″ rack-mountable card cage systems. Different applications require different styles of packaging. Low-volume needs tend to require standalone enclosures whereas high-volume needs are best met by high-density packaging (rail mount or rack mount). If real estate is a constraint in your system and packaging styles are a priority, then knowing what is available will be to your advantage.

Electrical connections and wiring methods also vary with packaging. In some cases, the effort of busing power to multiple standalone units can be drastically minimised by using card cage or plug-in backplane systems that bus the power for you. These systems allow the user to bring power to only one terminal block and internally bus the power to all associated channels. In addition, they separate the electronics from the wiring terminals and allow the removal or replacement of a module without rewiring.

Other forms of packaging lend themselves to a more modular approach. DIN rail packaging, for example, is an expandable, optimised way to mount any quantity of signal conditioners that use conventional wiring methods. Card cage and backplane systems can be cost-effective when most of the channels or points are fully utilised. Standalone units are cost-effective for low quantity needs; if they are designed in a modular fashion, the price per point becomes evenly distributed as quantities increase.

Knowing your quantity needs, anticipated growth needs and available space can help save dollars on your signal conditioner purchases. Many manufacturers offer the same signal conditioners in a variety of packages, so you should explore all packaging options.

Repairability

As with all purchases, you should consider future requirements and repairability when selecting signal conditioners. For example, products using insertion technology are easier to repair and maintain than potted, disposable surface-mount packages. Knowing how devices are manufactured will help you determine their repairability. If a conditioner can be repaired and maintained rather than discarded, you will save a lot of money in years to come.

In summary

The importance of comparing specifications and features before selecting a signal conditioner cannot be emphasised enough. Accuracy, adjustability, isolation, SWC, RFI/EMI, packaging and repairability should all be involved in your price vs performance equation. If you take these specifications too lightly, you could pay dearly in time and money in years to come.

Sampling gases and volatile liquids: essential strategies

Following gas sampling best practices can improve product output and reduce fugitive emissions.

Planetary gearbox supports global success of composting solution

New Zealand company Global Composting Solutions is having international success with its...

5 things to consider before implementing a UPS

UPS systems play a vital role in the health of your control cabinet: consider these five things...