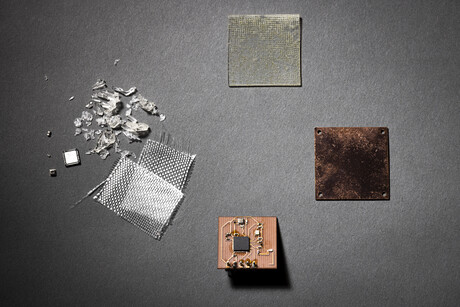

Recyclable circuit board turns to jelly for disassembly

PCBs — which house and interconnect chips, transistors and other components — typically consist of layers of thin glass fibre sheets coated in hard plastic and laminated together with copper. That plastic can’t easily be separated from the glass, so PCBs often pile up in landfills, where their chemicals can seep into the environment. Or they’re burned to extract their electronics’ valuable metals like gold and copper. This burning, often undertaken in developing nations, is wasteful and can be toxic — especially for those doing the work without proper protections.

A team led by researchers at the University of Washington developed a new PCB that performs on par with traditional materials and can be recycled repeatedly with negligible material loss. Researchers used a solvent that transforms a type of vitrimer — a cutting-edge class of sustainable polymers — to a jelly-like substance without damaging it, allowing the solid components to be plucked out for reuse or recycling.

The vitrimer jelly can then be repeatedly used to make new, high-quality PCBs, unlike conventional plastics that degrade significantly with each recycling. With these “vPCBs” (vitrimer printed circuit boards), researchers recovered 98% of the vitrimer and 100% of the glass fibre, as well as 91% of the solvent used for recycling.

The researchers have published their findings in Nature Sustainability.

“PCBs make up a pretty large fraction of the mass and volume of electronic waste,” said co-senior author Vikram Iyer, a UW assistant professor in the Paul G. Allen School of Computer Science & Engineering. “They’re constructed to be fireproof and chemical-proof, which is great in terms of making them very robust. But that also makes them basically impossible to recycle. Here, we created a new material formulation that has the electrical properties comparable to conventional PCBs as well as a process to recycle them repeatedly.”

Vitrimers are a class of polymers first developed in 2015. When exposed to certain conditions, such as heat above a specific temperature, their molecules can rearrange and form new bonds. This makes them both ‘healable’ (a bent PCB could be straightened, for instance) and highly recyclable.

“On a molecular level, polymers are kind of like spaghetti noodles, which wrap and get compacted,” said co-senior author Aniruddh Vashisth, a UW assistant professor in the mechanical engineering department. “But vitrimers are distinct because the molecules that make up each noodle can unlink and relink. It’s almost like each piece of spaghetti is made of small Legos.”

The team’s process to create the vPCB deviated only slightly from those used for PCBs. Conventionally, semi-cured PCB layers are held in cool, dry conditions where they have a limited shelf life before they’re laminated in a heat press. Because vitrimers can form new bonds, researchers laminated fully cured vPCB layers. The researchers found that to recycle the vPCBs they could immerse the material in an organic solvent that has a relatively low boiling point. This swelled the vPCB’s plastic without damaging the glass sheets and electronic components, letting the researchers extract these for reuse.

This process allows for several paths to more sustainable, circular PCB lifecycles. Damaged circuit boards, such as those with cracks or warping, can in some cases be repaired. If they aren’t repaired, they can be separated from their electronic components. Those components can then be recycled or reused, while the vitrimer and glass fibres can get recycled into new vPCBs.

The team tested its vPCB for strength and electrical properties, and found that it performed comparable to the most common PCB material (FR-4). Vashisth and co-author Bichlien H Nguyen, a principal researcher at Microsoft Research and an affiliate assistant professor in the Allen School, are now using artificial intelligence to explore new vitrimer formulations for different uses.

Producing vPCBs wouldn’t entail major changes to manufacturing processes.

“The nice thing is that a lot of industries — such as aerospace, automotive and even electronics — already have processing set up for the sorts of two-part epoxies that we use here,” said lead author Zhihan Zhang, a UW doctoral student in the Allen School.

The team analysed the environmental impact and found recycled vPCBs could entail a 48% reduction in global warming potential and an 81% reduction in carcinogenic emissions compared to traditional PCBs. While this work presents a technology solution, the team notes that a significant hurdle to recycling vPCBs at scale would be creating systems and incentives to gather e-waste so it can be recycled.

“For real implementation of these systems, there needs to be cost parity and strong governmental regulations in place,” Nguyen said. “Moving forward, we need to design and optimise materials with sustainability metrics as a first principle.”

Originally published here.

Omron and Cognizant partner on IT–OT integration

Omron Corporation and Cognizant have announced they have signed a strategic partnership to...

Greensteel Australia to build next-generation steel mill

Greensteel Australia has announced it has placed an order to purchase equipment for its...

Researchers design water filter that removes PFAS molecules

Researchers at Monash University have developed a water filtration membrane that effectively...