NZ Steel advances lower emissions steel ambitions

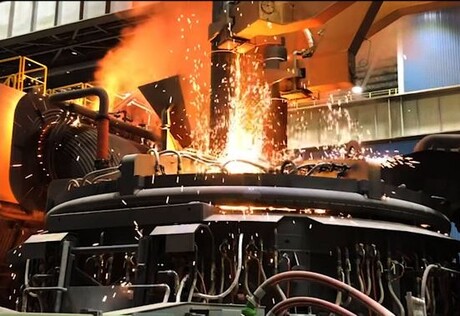

New Zealand Steel Chief Executive Robin Davies has announced that the company is set to exceed its initial greenhouse gas (GHG) reduction targets with its planned electric arc furnace at the Glenbrook steelworks.

He said that New Zealand Steel’s partnership with government and industry to change the way it makes steel at Glenbrook could cut greenhouse gas emissions by up to one million tonnes per annum — 200,000 tonnes more per annum than previously advised. Davies also expects commissioning of the new plant to be brought forward to the end of 2025, rather than 2026.

In May 2023 New Zealand Steel announced it would build a new electric arc furnace at its Glenbrook steelworks within the next three years as part of its move to lower emissions production, reducing the site’s annual GHG emissions by up to 800,000 tonnes once commissioned. The investment is also intended to secure the future of steelmaking at New Zealand Steel’s plant, south of Auckland.

“The electric arc furnace project is progressing at pace with civil works well underway — we are on track to deliver this significant reduction in the country’s emissions; in fact, we are very pleased to advise the design phase shows we can go further, faster than originally planned,” he said. “We are now looking at up to a one million tonne reduction in our annual GHG emissions, with starting commissioning brought forward to the end of 2025.

“Taking up to a megatonne of emissions out of the country’s current annual carbon footprint will make a significant contribution to meeting New Zealand’s emissions reduction targets.”

The project has been supported by EECA (Energy Efficiency and Conservation Authority) as a bespoke partnership with New Zealand Steel as a large energy user and emitter.

Davies says renewably generated electricity and local scrap steel supply are central to the plan to almost halve New Zealand Steel’s emissions.

“To enable this push to go further, faster, we have gone to market for additional power purchase agreements to supplement the original competitive and innovative supply agreement reached with Contact Energy last year.”

The electric arc furnace provides New Zealand Steel with significantly more production flexibility so that it can scale down production at times of peak demand or supply shortages such as those experienced this winter.

“It also means recycling more domestic scrap steel in New Zealand, rather than it being shipped overseas to be recycled, further strengthening domestic waste-to-value solutions,” he added.

Since announcing the electric arc furnace last year New Zealand Steel has secured supply contracts with Global Metal Solutions and SIMS for hundreds of thousands of tonnes of domestic scrap steel.

In terms of installation of the electric arc furnace itself, the site is currently being prepared and New Zealand Steel expects parts of the arc furnace to begin arriving from its design and supply partner — Italian firm Danieli — in February 2025.

“I’m excited to see this state of the art technology arriving on our shores and being installed here at Glenbrook,” Davies said.

Australian industry contracts in F-35 program worth over $5 billion

The Department of Defence has announced that Australian industry has reached a milestone of more...

Mitsubishi and Rio Tinto to participate in hydrogen-based ironmaking

Mitsubishi, Rio Tinto, Primetals (UK) and voestalpine (Austria) are collaborating on a...

Greensteel Australia to build next-generation steel mill

Greensteel Australia has announced it has placed an order to purchase equipment for its...