Coffee grounds and hydrogen from waste for green steel

The UNSW SMaRT Centre has had three scientific papers1,2,3 published which show that waste coffee grounds and hydrogen from other wastes can be used as part of its patented green steel technology.

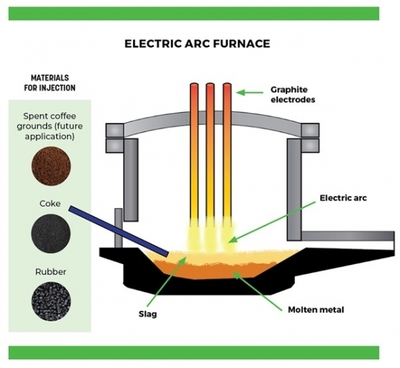

In the latest research breakthroughs on SMaRT@UNSW’s Green Steel Polymer Injection Technology (PIT), industrial trials with partner Molycop have shown various wastes can be used to more sustainably make steel in electric arc furnaces.

Wastes including plastic and coffee grounds now join waste rubber tyres as alternative sources of coke and coal as previously vital ingredients as carbon sources for steelmaking, and can provide the element hydrogen which vastly improves the efficiency and energy required for the manufacturing process.

“Steelmakers have to meet the demands of quality requirements,” said UNSW SMaRT Centre Director, Professor Veena Sahajwalla. “The metal that gets produced doesn’t have any memory of whether the parent material that went in was coal or coffee.

“We’ve proven that it does the job at a comparable level, so we’re going to be at least sitting at an equivalent performance. If I’m going to be so bold and brave, I’d love to show that it can do even better.

“We (Australian steelmakers) are leaders in the space globally,” she added. “We’re the first to be able to take all of these technological advances and show that it can be done.

“The ideal would be if we completely eliminate the coke. If you have a combination of materials, you get a better outcome because you’re able to fine-tune and customise green steel and take the kinds of materials that do the best job.”

“This is not a waste, it’s a really useful resource,” she said. “It’s going to be an interesting shift towards valuing our waste resources and thinking about those innovative supply chains where recycling and manufacturing can be coupled together.”

References

- Regeneration of hydrogen through thermal micronisation of end-of-life polymers for sustainable reduction of iron oxide, Fuel Processing Technology, vol. 226, Science Direct.

- Synthesis of Value-Added Ferrous Material from Electric Arc Furnace (EAF) Slag and Spent Coffee Grounds, Pyrometallurgical Processing of Secondary Resources, 26 April 2021, Springer.

- A novel reforming approach of utilizing spent coffee grounds to produce iron, Resources, Conservation and Recycling, vol. 163, Science Direct.

New liquid catalyst to transform chemical manufacturing

A major Australian breakthrough in liquid catalysis could transform how essential products are made.

Aussie manufacturing conditions improve at fastest pace since 2022

S&P Global has reported that Australia's manufacturing sector experienced its strongest...

The engineering workforce is critical to securing Australia's future

Engineers Australia says the next federal government needs to prioritise real action on...