Aussie scientists make self-folding straw

Scientists at The Australian National University (ANU) have made a new material which folds itself into a straw-like tube when it comes into contact with water, then propels the liquid through the tube. The new material can be used to easily create cheap fluid distribution systems that could be used for medical sample analysis, biological sensors or microrobotics.

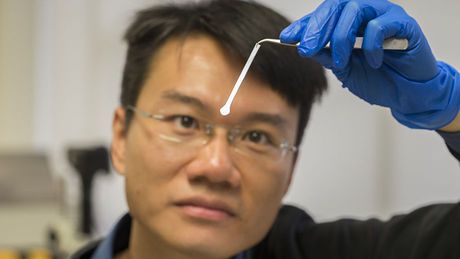

Lead researchers William Wong and Associate Professor Antonio Tricoli said the paper-like material can respond to a small water droplet by folding in a tube several centimetres long. The water then moves through the tube.

“If we place a drop of water at one end, the material will curl into a tube, delivering the liquid up to 15 centimetres away,” said Wong, from the ANU Research School of Engineering.

“This enables a rapid self-assembly of complex shapes, such as bent, curved and splitting channels, that are a building block for microfluidic systems.”

Previous studies have harnessed surface tension to fold materials into origami shapes, such as tiny cubes or pyramids, but this is the first to use the effect for a tube of several centimetres.

The team at the Nanotechnology Research Laboratory of the Research School of Engineering found that the channelled water could even navigate challenging shapes such as T-intersections, forks and curves.

The ability to control and direct the flow of tiny amounts of liquid will be useful where there are inherent dangers to humans, such as highly reactive environments, or with biosensors of infectious diseases. The material is cheap and the manufacturing process is non-toxic and will scale well to industrial levels.

Co-researcher Dr Dave Nisbet, from the ANU Research School of Engineering, said the material was also compatible with living tissue.

“Because it is safe, this could be used for cheap sensors to diagnose cancer and other diseases. It will be really important for biology,” he said.

The material is made of two thin layers of nanofibres sandwiched together. The top functional layer, made of polycaprolactone nanofibres, is the water-responsive, energy-dense component (superhydrophilic), which draws the material up around the water droplet.

The bottom layer is made of microfibres of polyvinylchloride (PVC), which is strongly water-repellent (superhydrophobic) and prevents the water from escaping once the material has rolled into a tube.

Associate Professor Tricoli, the research group leader, said the folding motion could also be used to move limbs that are attached, similar to the way the fronds of the Asian Mimosa plant close up when touched.

“We can make the material roll up with water, and then unroll again by adding ethanol. This gives us chemically activated movement that could be really useful in biological sensors and actuators,” said Tricoli.

The research is published in Science Advances.

Mars Wrigley to boost Asquith factory with new production line

Mars Wrigley Australia is installing a new production line at its Asquith factory to boost...

Welding body calls for a nation-building approach to combat Trump's tariffs

Weld Australia believes that US tariffs offer Australia a unique opportunity to carve out a new...

New free TAFE courses aim to develop manufacturing skills

The NSW Government has announced four new free TAFE courses designed to upskill Australians and...