Next-gen electric vehicle batteries take a salt bath

A new generation of rechargeable lithium batteries may soon be ready to jump-start the electric vehicle industry, thanks to the humble salt bath.

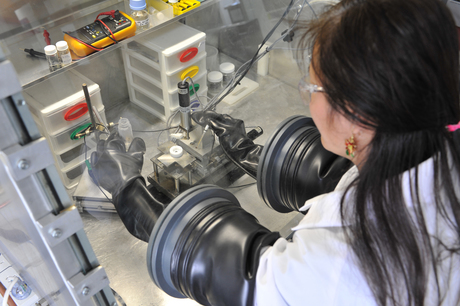

CSIRO scientists, in collaboration with RMIT University and QUT, have demonstrated that pre-treating a battery’s lithium metal electrodes with an electrolyte salt solution extends the battery life and increases performance and safety.

The method is expected to spark the development of next-gen energy storage solutions which could see electric vehicle drive range and battery charge improve to a point where electric vehicles could be competitive with traditional petrol vehicles.

“Our research has shown by pre-treating lithium metal electrodes, we can create batteries with charge efficiency that greatly exceeds standard lithium batteries,” said CSIRO battery researcher Dr Adam Best.

The pre-treatment process involves the immersion of lithium metal electrodes in an electrolyte bath containing a mixture of ionic liquids and lithium salts, prior to a battery being assembled.

Ionic liquids, or room temperature molten salts, are a unique class of material that is clear, colourless, odourless and non-flammable.

When used in batteries these materials can prevent the risk of fire and explosion — a known rechargeable battery issue.

The salt bath pre-treatment adds a protective film onto the surface of the electrode that helps stabilise the battery when in operation.

“The pre-treatment reduces the breakdown of electrolytes during operation, which is what determines the battery’s increased performance and lifetime,” Dr Best said.

Batteries that have undergone the process can also spend up to one year on the shelf without loss of performance.

QUT researcher Associate Professor Anthony O’Mullane said the method is readily transferrable to existing manufacturing processes.

The electrolyte salt solutions, to which CSIRO holds patents, come in a range of chemical compositions.

The team of scientists is currently developing batteries based on this technology and is looking for partners to help bring these materials and devices to market.

The research was published in Nature Communications.

Researchers developing automated electronics disassembly

Over 80% of e-waste ends up in landfill or incinerators, including all the valuable raw...

Coming in May: Australian Manufacturing Week 2025

Registration is now open for the biggest precision engineering manufacturing show ever held in...

2025 Thought Leaders: Martin Broglia

Martin Broglia of Bonfiglioli Australia and New Zealand discusses the business of sustainability...