Key success factors for manufacturers in 2017

By Antony Bourne, Director of Industrial and High-tech Manufacturing, IFS

Friday, 13 January, 2017

Bridging the skills gap and boosting services will be top priorities for manufacturers in 2017. And IoT? Today, 50% of the costs of IoT projects go to integration. 2017 will see many manufacturers realising they already have IoT solutions — now they need to integrate them better to leverage the full benefits.

Prediction 1: Over 80% of manufacturers will realise they already have IoT solutions. The question is: how easily integrated are they?

After years of hype, we tend to forget that many manufacturers already have Internet of Things (IoT) capabilities — and have had for years. They just might not identify them as such. But systems like SCADA and PLCs have efficiently gathered performance data from equipment since the ’80s and ’90s, and many continue to do so. So manufacturers need to think carefully about which data performance tracking technology is most relevant to them. For those producing large-scale capital equipment to be deployed in the field, new sensor-enabled data gathering technology is a fantastic value-add. It enables them to offer maintenance and services around the clock, in tough environments — a serious competitive edge.

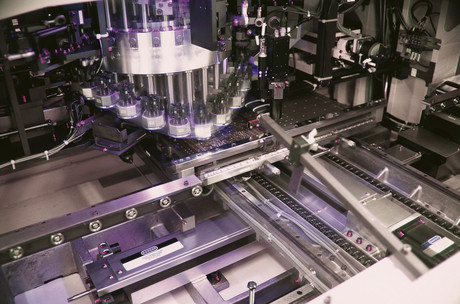

But for manufacturers producing a higher volume of smaller products in-house, for example, IoT field sensors and monitoring would be hugely costly. In these cases, preventing problems before the goods leave the factory is the priority. So if SCADA or PLC do the job, an IoT solution is already effectively up and running. Currently, 50% of the cost of implementing IoT projects goes to integration — some of it, for sure, unnecessarily. For these high-volume manufacturers, an open-architecture ERP system that lets them integrate their existing legacy systems without costly integration could be money better spent. So carry out an audit. Identify which KPIs, measured where, really count for your business. Today’s IoT offers tremendous advantages for some, but for others it can be a costly irrelevance.

Prediction 2: In the next three years, apprenticeships will become more important than degrees

The future of every industry depends on its people. And sometimes good people are hard to find. Across Europe and the US, manufacturers are wrestling with a skills gap. In 2017, solving the skills shortages could bring in a new era of apprenticeships, in-house peer training and manufacturers working more closely with local education institutions to get younger talent into the industry.

A Deloitte study found “over the next decade nearly 3.5 million manufacturing jobs in the US will likely need to be filled. The skills gap is expected to result in 2 million of those jobs going unfilled”. In Europe the picture is similar. 82% of the executives surveyed in Deloitte’s report believe the skills gap will impact their ability to meet customer demand, while 78% believe it will impact their ability to increase productivity and implement new technologies.

The study shows that a career in manufacturing is ranked consistently low. Only 37% said they would encourage their children to go for a manufacturing career. So what is to be done?

Manufacturers need to start taking a more proactive role in spotting and training young talent. Apprenticeships and in-house training will move up the agenda. Take British Engines, a global engineering group producing technology for a whole range of industrial sectors. During a recent recruitment drive, they turned away from LinkedIn and reached out instead to young talent in their local area. Ads were placed on local public transport and in local papers. The success of their campaign reflects the findings of a 2016 Wall Street Journal report: “… hard-to-fill roles are middle-skill positions, such as maintenance technician, that require education or training beyond high school, like an apprenticeship or a course at community college”. For young talent, apprenticeships mean solid, bankable skills with no debt attached. For employers, it means the skills they really want.

There are also new types of skills that will particularly high in demand in the future. A factory will often consist of thousands of IoT sensors and a number of new devices connected to the internet continuously gathering data. This will result in greater needs to analyse large data volumes and automating key processes based on data. For young apprentices, the technical, analytic and personal skills learnt are gifts that will keep giving. In some countries, manufacturing salaries are higher than the national average. So bring in new blood. Think carefully about how you build up your skill set. Ask yourself: who will benefit my company more in the long run — a graduate with a degree, or a young, eager professional schooled in the reality of my business and committed to its success?

Prediction 3: 75% of mid-sized manufacturers will adopt ‘servitisation’ before 2018

It’s not easy being a manufacturer: the price of manufactured goods in the West has been falling for decades. The Producer Price Index for major European or US states all show the same trend: from 2015–2016 the price of manufactured goods in the UK fell 0.7%, 1.4% in Finland and 0.29% in Germany. Some years prices may creep up, but the big picture is clear: in 10 years’ time Western manufacturers will no longer be able to compete on price. The days of ‘make it and sell it’ as a default business model are over. So how else can manufacturers compete?

Jargon aside, ‘servitisation’ is, quite simply, understanding the bottom line of what your customers really want. Take Xerox: after decades of producing evermore sophisticated photocopiers, in 2000 they asked themselves: what is it our customers really want? Great photocopying machines, or excellent-quality printed documents on demand, whenever and however? Managed Print Services was born. By 2013 Xerox had transformed from product centric to service centric. The results for Xerox customers were broad and positive: Reuters achieved a 19% cut in its TCO, Sandwell Council a 30% cut in printing costs, PwC met 100% of its security needs, and the UK’s Department of Work and Pensions had a 36% cut in electricity consumption. For Xerox, too, the rewards were significant: a sharper competitive edge, more predictable revenue streams and a portfolio of customers who are in it for the long haul.

IFS customer Beijer Electronics is another great example. A global innovator in industrial automation and data, Beijer makes smart black-box systems that optimise I/O devices. With copies of their technology appearing at ever cheaper prices and hardware sales predicted to decline, Beijer needed to be both proactive and innovative. So the company servitised, launching the online WARP Engineering Studio. With WARP customers can integrate, customise and better control how they use Beijer’s products. WARP provides premium services customers can operate on top of their black boxes, and speeds up their processes. For Beijer, selling products as a service through WARP means customers will not want, or need, to compare them on product price. The capabilities the Studio delivers are what the customer value. Servitisation gives Beijer a highly strategic competitive edge. It lets them monetise their vast in-house expertise, harnessing it to make sure that their customers get what they really want.

So how can manufacturers start building their services? Step one: start small. Are you offering customers spare parts and consumables that add value to their purchase? Step two: what maintenance services do you offer customers? Built-in maintenance de-risks a customer’s purchase. Service contracts that guarantee, for example, 99% uptime, can be optimised through live IoT feeds, where you the supplier schedules preventive maintenance that lets the customer focus on their core business. Step three is all about sharing risk — and revenues. Selling capabilities rather than just equipment. Customers pay a monthly fee for a guaranteed service, and manufacturers get a solid, predictable revenue stream independent of falling product prices.

The journey isn’t easy: sales cycles can be longer, new service departments may need to be created, revenue gaps can occur before services mature. But when manufacturers move beyond the factory walls and ask themselves what it is their customers really need from their products, new relationships, growth and opportunity can flourish.

Climate-friendly electricity from ammonia

Researchers the Fraunhofer Institute have developed a high-temperature fuel cell stack that can...

Digitalised, sustainable battery cell production

German researchers have developed a flexible winding system for battery cells that is embedded in...

Expired deadline threatens critical infrastructure as compliance lags

The deadline for achieving cybersecurity framework alignment for the SOCI Act expired on 17...