Load testing to be available from new SEW Service Centre in Mackay

Believing that load testing a gearbox or drive will ensure that potential problems are identified before the unit goes back into service, SEW-Eurodrive will implement a state-of-the-art system to load test up to 500 kW power and up to 600,000 Nm torque. Spin test or partial load test up to 1.5 MW will also be available.

In addition to load testing the gearbox, in most cases SEW-Eurodrive will be able to load test the entire gearbox, motor and swing-base assembly. This can be done as a shaft-mounted assembly, which closely replicates site mounting.

According to Daniel Dallari, sales & operations manager – Far North Queensland, the load testing facility will be a great addition to the new service centre in Mackay. “SEW’s load testing capability will be the first of its kind in Queensland,” Dallari said. “Other gearbox repairers only spin test the overhauled gearboxes and any potential problem will only be revealed after the unit is back in operation.”

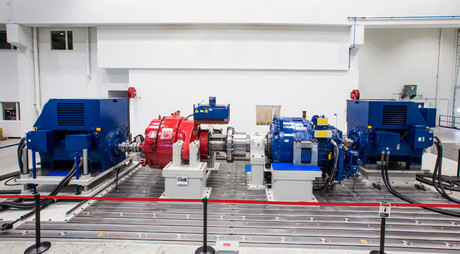

SEW-Eurodrive collaborated with CNC Design — a Melbourne based company — on the state-of-the-art load testing system. CNC Design has extensive experience in GEARTest load testers for both industrial and wind turbine gear units in Australia and USA.

GEARTest is a back-to-back set-up to test the gearbox up to 100% full load with minimum energy consumption. The drive motor is connected to the gearbox undergoing the test. The output shaft of this gearbox is in turn connected to a special-purpose SEW speed-matching test gearbox unit, itself driving another motor acting as a generator. The principal is the same for both industrial and wind turbine gearboxes.

The test rig is controlled by an advanced motion control system, so the load cases and test sequences are flexible and can be adjusted to the specific test plan for each gearbox. This is set up and monitored via a user-friendly operation station. Additionally, the specific software for sound and vibration measuring is integrated in the solution as required.

SEW-Eurodrive will conduct a number of tests to determine the condition of the gearbox during the load testing phase. The load test will load the bearings and gearing, avoiding gear mesh backlash that affects vibration analysis and ensuring FFT readings will identify any potential bearing, gear or shaft defect. Loaded gear tooth patterns will detect potential misalignment, including misalignment caused by load, speed or temperature. A test protocol will be provided for each performed test and will remain both with the gearbox documentation and also stored electronically for evaluation later on. Load testing allows measuring noise and checking compliance with noise requirements.

SEW-Eurodrive also guarantees that all gear replacements will be manufactured with state-of-the-art gear technology.

A benefit of completing this load test from the service centre in Mackay will be that maintenance and service personnel will be able to visit the facility to witness the load testing phase.

HRS to showcase turnkey processing solutions at APPEX 2024

HRS Heat Exchangers will be showcasing a range of turnkey line solutions for the food and...

HARTING opens production plant in Vietnam

HARTING's new 2500 m2 production site in Hai Duong, Vietnam, will manufacture the...

Oxair and Cobalt Blue combine for future of energy storage

Oxair has supplied its onsite oxygen and nitrogen generators to a Broken Hill mining operation...